In addition to parts and refurbishments for your apron feeders, Metso also offers the following services that help you get the most out of your machine.

Life Cycle Services

Life Cycle Services (LCS) take the entire range of services and conveniently bundles them into customizable, easily manageable packages, ranging from the basics to more complete solutions, depending on the scale of your needs. Packages are equipped to cover single-event equipment shutdowns or span multiple years, measured against strict KPIs.

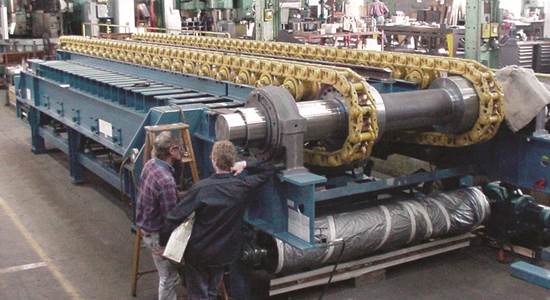

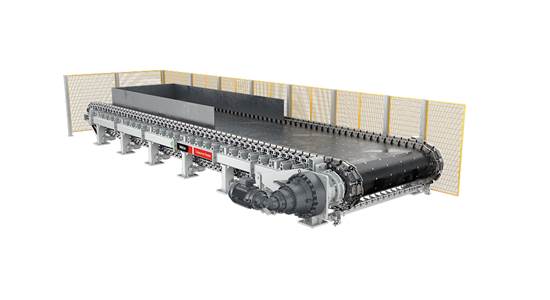

Field services

Metso offers a comprehensive set of field services to help meet your maintenance, repair, installation and refurbishment needs. Each service is fully customizable to your exact requirements. Our highly specialized services cover all Metso and 3rd party apron feeders.

Inspections and equipment audits

Regular inspections help prevent unplanned mechanical and electrical failures from having a direct effect on your apron feeder’s availability and productivity. Metso also offers other services that help you get the most out of your machines.

- Certified global service team

- Expert assessment and recommendations

- Minimized downtime

Repair and maintenance services

Our service experts provide regular and corrective maintenance services, as well as preventive maintenance options. Repair services are available both on-site and at our global repair centers, depending upon the scope of work required. Our repair facility network offers an extensive range of services stretching from straightforward parts replacement to complete equipment reconditioning.

- Global network of service centers

- Skilled and certified technicians

- Cutting-edge technology and tools

- Safe and consistent service standards

Training

Metso offers training programs based on expert knowledge of equipment and maintenance procedures. Training programs include online e-training, hands-on modules, specialized courses on apron feeder, along with safety and maintenance training in accordance with global best practices.

- Improved employee motivation

- Full utilization of equipment features

- Maximized productivity

- Safer operation