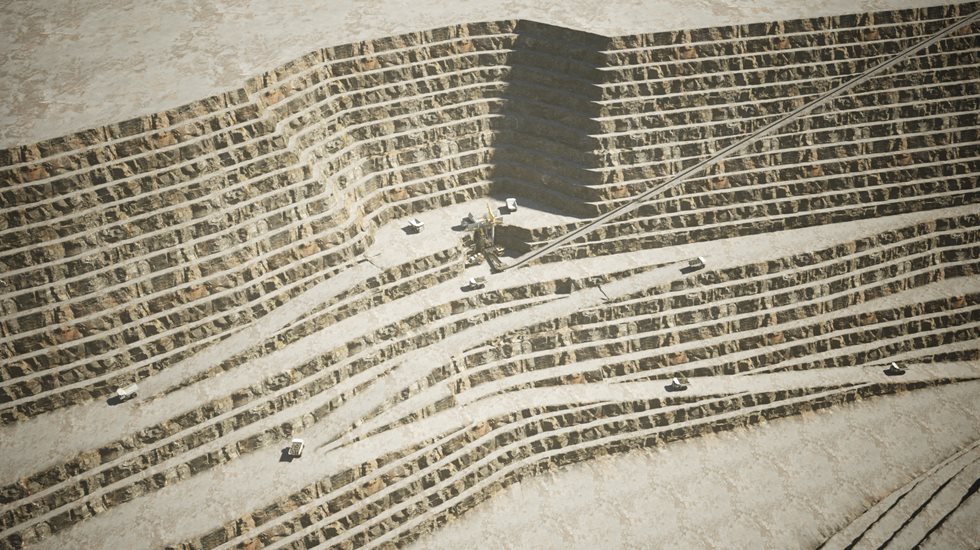

Mining operations are impacted by declining head grades. More material needs to be moved from greater depths to maintain concentrate production levels. This affects productivity and energy consumption, which directly correlates to the mine’s profitability and sustainability.

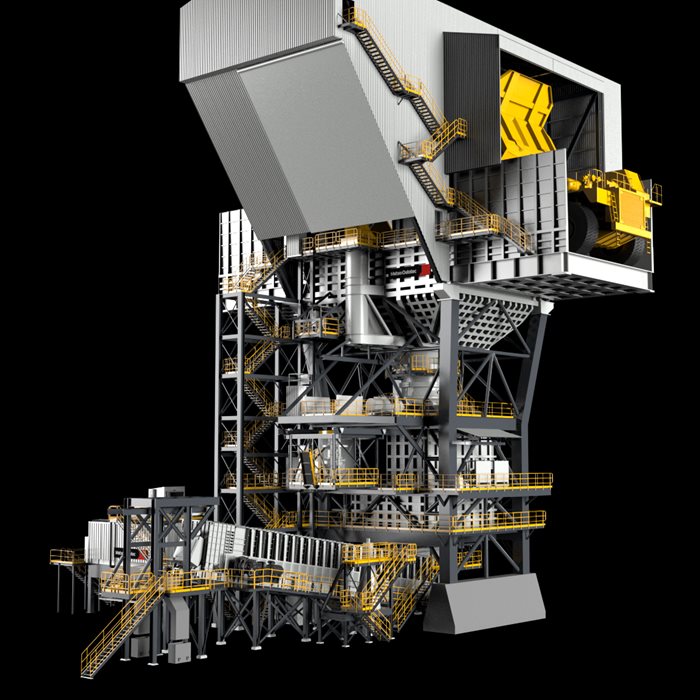

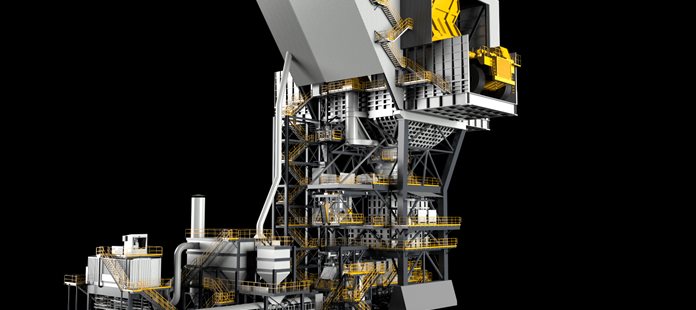

To better meet these challenges, Metso in-pit crush and convey (IPCC) solutions provide an integrated solution consisting of crushing, conveying, and stacking equipment combined with IPCC planning and life cycle services. The offering has been designed to ensure the highest productivity, energy efficiency, as well as maintainability.

Metso IPCC solutions are also a part of the Planet Positive portfolio.

Looking for even more content? Check out our brochure in the downloads below or read the recent interview done with International Mining - 'Gearing up for the next generation of IPCC applications'.