Benefits

- Standardized machine that can be easily customized to meet different customer requirements

- Improved operating safety and easy maintenance work

- Less brick wear through flexible punching machine strategies

- The design is optimized for lower manufacturing costs

Main features

New features

- Variable length of stroke as an option

- Temperature measurement

- Drilling unit for refractory can be docked to the machine frame

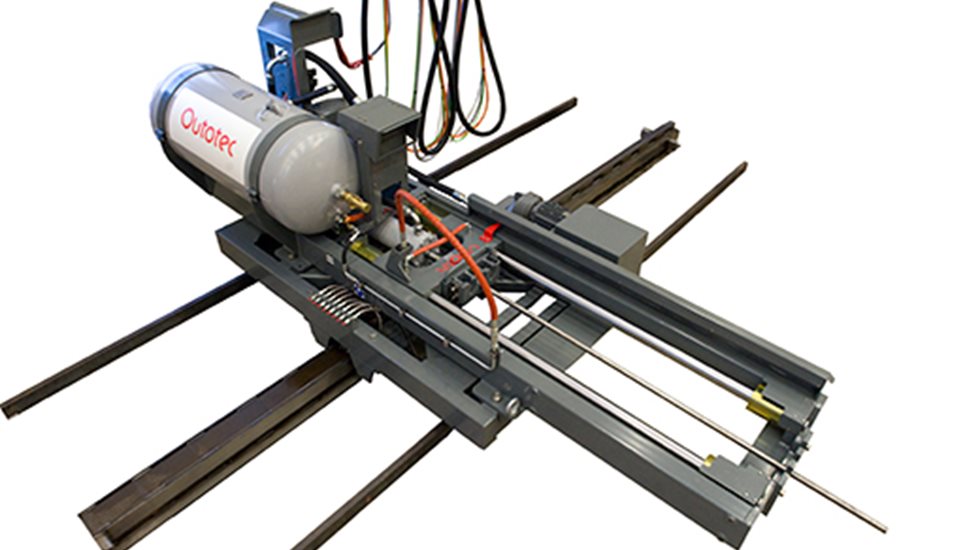

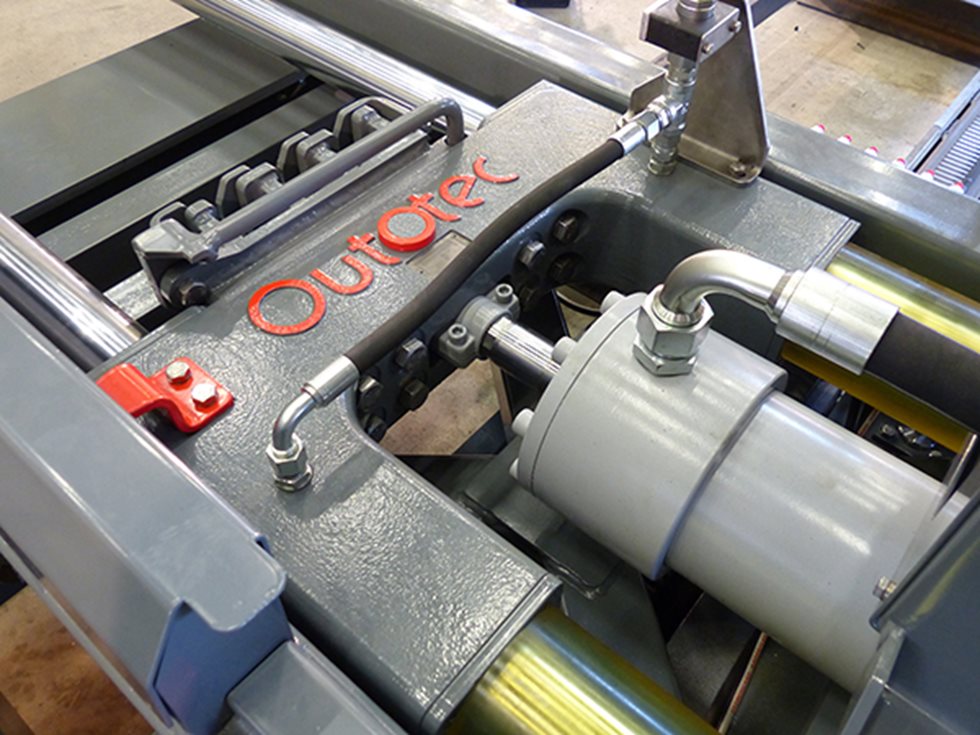

Heavy duty design:

- Mechanical and electrical components designed for harsh conditions

- Compact machine with flexibility in the steel frame to meet customer space requirement

- High and adjustable impact energy

Intelligent control system:

- User friendly interface with intelligent operation functions

- Can be operated manually or automatically from the control room or locally close to the machine

- Different automatic punching sequences can be selected, based on current process conditions

- Position of the punching machine is very accurate, within ± 2 mm

Short pay-back time:

- Control of the punching machine is done by the operator in the control room, no need for dedicated punching machine operators

- High availability thanks to proven and robust design