Situated 25km from Lephalale in South Africa’s Limpopo province, the Grootegeluk open-pit mine employs 2000 people, producing 18,8Mtpa final coal products using a conventional truck and shovel operation. The estimated minable coal reserve is 2800Mt, with a total measured coal resource of 4600Mt, from which semi-soft coking, thermal and metallurgical coal can be produced.

Grootegeluk has the world’s largest beneficiation complex where 8000 tonnes per hour of run-of-mine (ROM) coal is upgraded in six different plants.

Some 14.8Mt of annual production is transported directly to Eskom’s Matimba power station on a 7km conveyor belt with 1.5Mtpa of metallurgical coal being sold domestically to the metals and other industries. Grootegeluk also produces 2.5Mtpa of semi-soft coking coal, the bulk of which is railed directly to Mittal, SA, with the remainder making up 1Mtpa of semi-soft coking and thermal coal which is exported or sold domestically.

Project Overview

The two existing 70m Denver thickeners at Grootegeluk’s GG2 plant were initially constructed to accommodate feed from that site at a duty of 225tph at 7% w/w.

Over the last couple of years, additional streams from other plants were added, placing greater demand on the thickeners. The additional streams from plants GG2, 4, 5 and 6 not only increased the operating tonnages, but also contained a significant amount of fines. As a result of the new feed tonnages and material, a higher flocculant dose was needed, resulting in a reduction in underflow density and an increase of overflow sliming/pulping occurrences.

All this lead to poor thickener performance, increased down-time, significant water losses, as well as impacting the slimes dam capacity.

Grootegeluk Thickener Upgrade

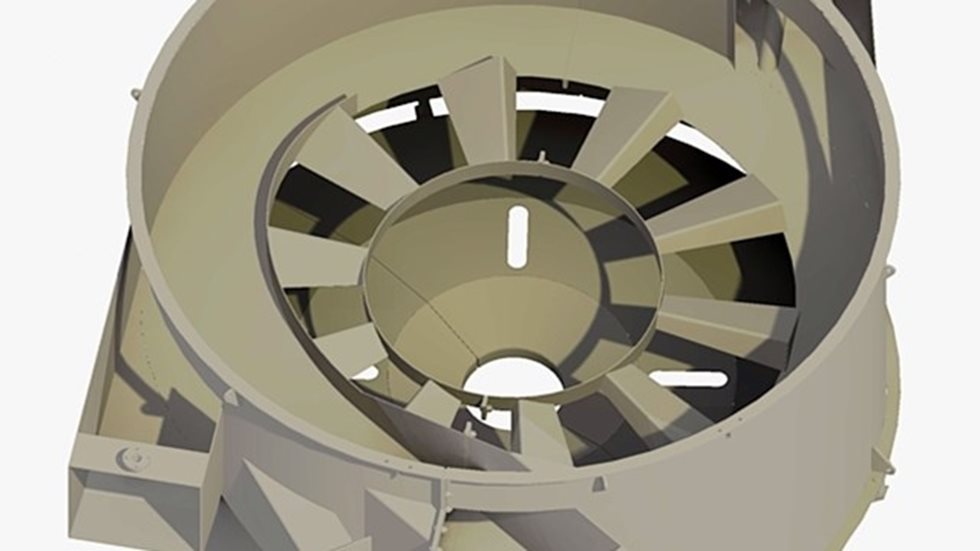

Exxaro Coal’s Grootegeluk site approached Outotec to assist with improving the performance of one of the thickeners. The newly developed Vane Feedwell TM was put forward as part of an option to resolve the issues affecting the GG2 concentrator. The Vane Feedwell TM components were retrofitted to the internals of the existing feedwell and consisted of vanes, a radially sloped shelf, and forced dilution - all standard Outotec Vane Feedwell TM design features.

The thickener upgrade on the first 70m thickener at the GG2 mine in April 2010 was planned ahead to coincide with an extended plant shut down. In addition to the Vane Feedwell TM, Outotec also retrofitted a new SCD rake drive mechanism, including a new platform and central column. A Turbodil TM for feed dilution and flocculant spargers were also installed to improve flocculant addition. A new set of thickener rakes, launder weir plates and local control panel were delivered along with instrumentation including, bed mass, bed level and drive torque.