The Yara Siilinjärvi plant is located in Finland and is owned by Yara International ASA, a Norwegian fertilizer company. Siilinjärvi is Western Europe’s only apatite mine. It produces apatite concentrate mainly for its Siilinjärvi phosphoric acid plant. Part of the concentrate is also dried and shipped to other Yara fertilizer plants. About one million tons of apatite concentrate are produced annually, creating approximately 10 million tons of tailings per year.

Background of the project

In 2015 Yara awarded Outotec the contract for a fullscale paste tailings plant at Siilinjärvi as an Engineering, Procurement and Construction (EPC) project. This paste plant delivered by Outotec increases tailings solids content, improves tailings beaching properties and extends the capacity and lifetime of the existing tailings storage facility. The paste plant has been operational since February 2017. Further details of this EPC project can be found separately in another Outotec case study on Yara.

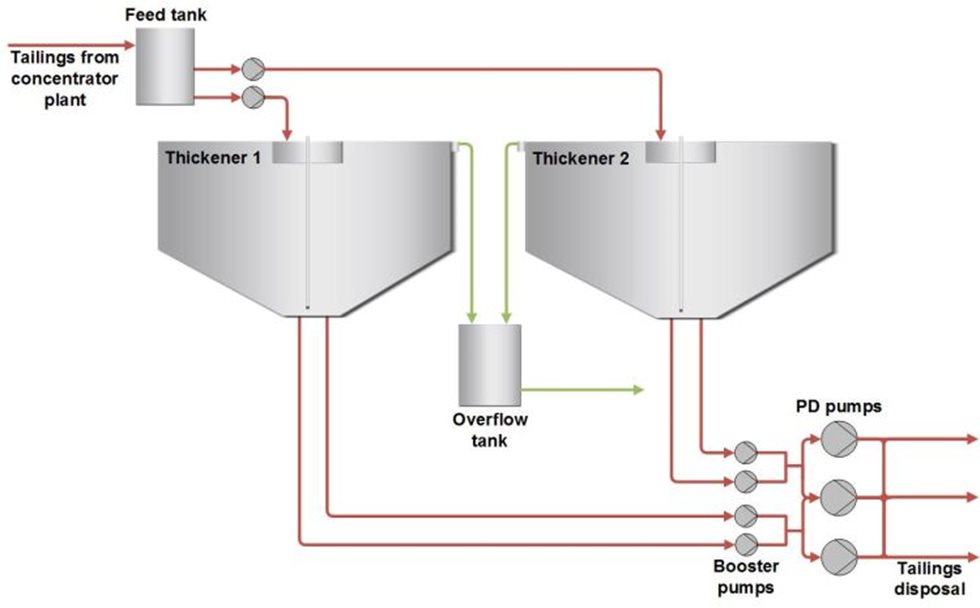

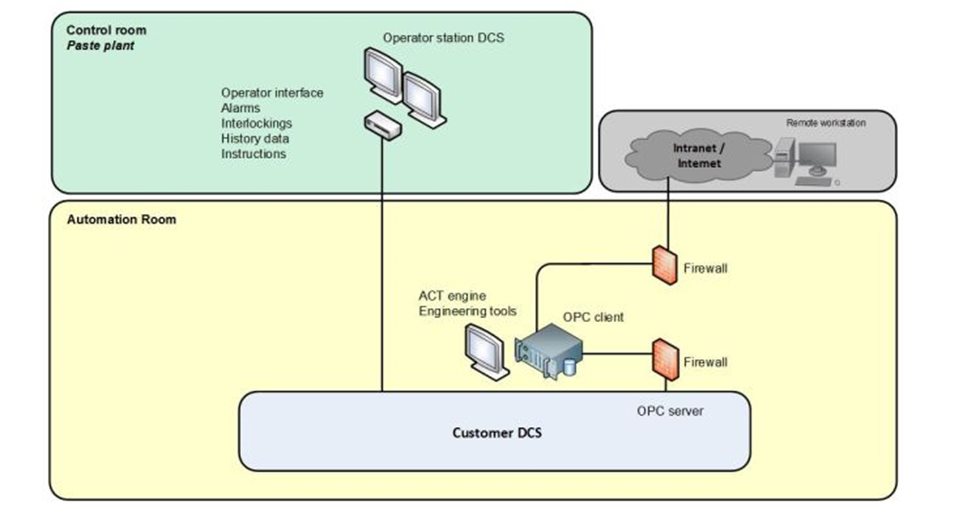

As part of the overall project, Outotec also designed and delivered an optimizing control system for the two paste thickeners at the tailings plant. This case study discusses the control application, its challenges and results following implementation at Yara.

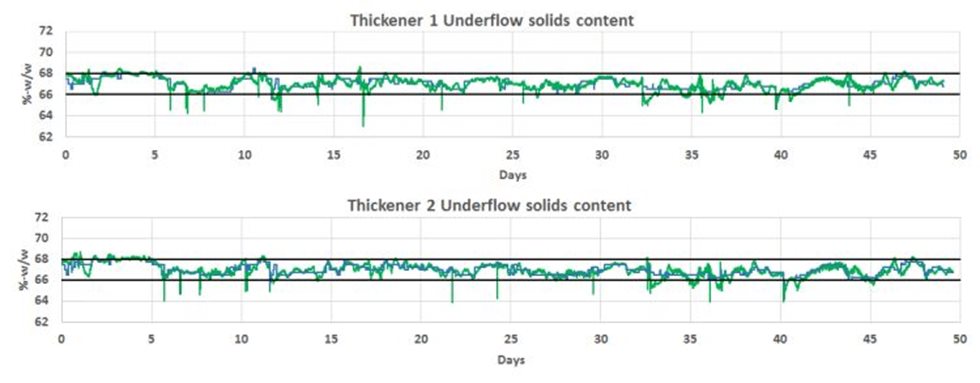

The new plant’s objective was to achieve a 68–70% solids underflow and at least two degree (3.5%) beach slopes, extending the tailings pond lifespan from 2020 to 2035. Factors such as the plant’s changing mineralogy and tailings feed fluctuations make it challenging to reach these solids underflow and beach slopes targets. It was determined that many of these challenges could be overcome with adequate process instrumentation and state-of-the-art control techniques.