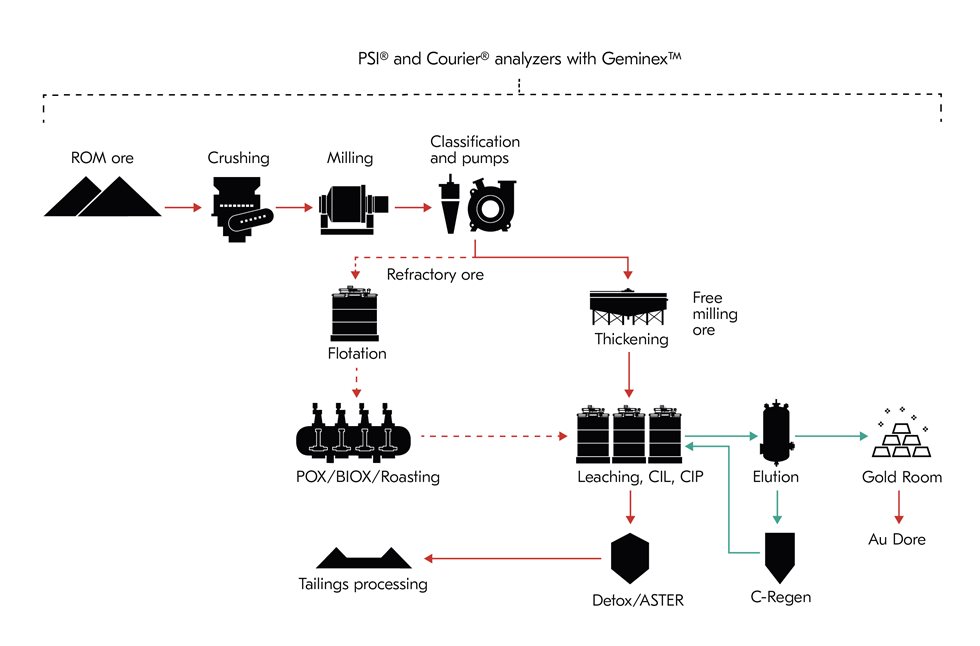

Process solutions from free-milling to refractory gold ores

Extensive industry experience in delivery of refractory gold projects

Minimizing risks through comprehensive research and testing

The modern gold rush

The combination of growing demand, fewer substitutes, and dwindling supply is inevitably causing the value and importance of gold to increase over time. There’s no doubt - it is truly the metal of the future.

The global gold market spans a diverse set of consumers and investors. While jewelry remains the primary application, investment in gold still holds a significant share of the total demand. Gold also plays a pivotal role as an industrial metal in a broad range of applications. This demand is driven by the electronics sector, which accounts for ~80% of gold used in technology.

Introducing Metso in gold

Sustainability

Our customers must satisfy the growing demand for minerals while managing deteriorating ore grades, and stricter sustainability requirements. To reach net zero - which is the goal for most leading mining companies - will require a shift towards renewables-based electricity and an increase in energy efficiency. This is where Metso’s Planet Positive offering steps in.

Our offering for the gold segment consists of technologies meeting our Planet Positive criteria:

- Energy efficient crushing and grinding

- Best in industry slurry mixing solutions including FlowBottom

- Integrated water balance management through HSC software

- Complete range of digital solutions including Mill and CIL optimizer