Why partner with Metso?

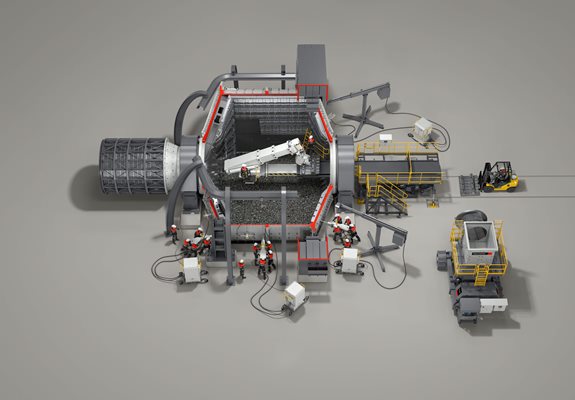

Widely recognized as a technology leader in grinding and mill reline equipment

Solutions built around what you want to achieve with a focus on safety throughout

1500+ field technicians with rapid response time

From standard to comprehensive programs

Metso is widely recognized as a technology leader in grinding and mill reline equipment, which makes us much more than a service and wear parts supplier – we are true grinding experts. We know the functional parameters, mechanics, kinematics and forces the mill is subjected to in operation. More than just being a contractor on mill reline projects, we are committed to achieving results together:

- Decrease your shutdown time

- Improve your mill availability

- Boost your liner utilization

- Increase your total productivity