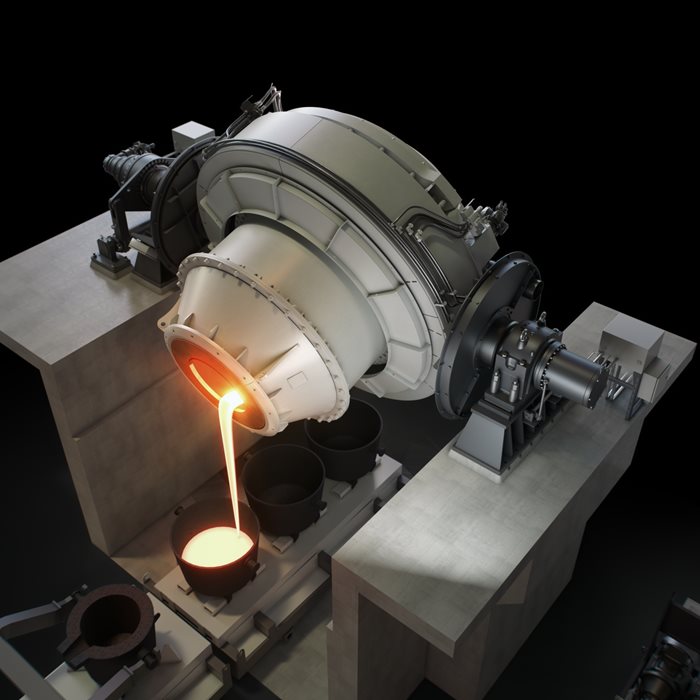

The batch process starts with the charging of material to the furnace. Depending on the process and raw materials to be charged, this is achieved in different ways. Smelting and converting are performed by introducing water-cooled burner and converting lance.

When the processing is finished, the furnace is tilted to pour the slag and alloy to ladles located on a ladle transfer car below the furnace. The process is very compact and fully encapsulated, making it possible to ventilate the whole section to the bag filter and prevent stray emissions. Metso's Outotec process for Kaldo is a well-established solution and has substantial references globally.

Specifications

- Complete, optimized process solutions for a diverse range of feed materials based on decades of technical expertise.

- Fully automated smelting solutions enable safe, stable operations leading to high recovery and availability.

- Minimized investment risk due to proven technology.

- Successful reference projects delivered for customers globally.

- Proven environmental compliance.

- Technology delivery backed by pilot testing, process guarantees, and advisory services enables fast ramp-up to design capacity.

- Optimized total cost of ownership.