Improved safety

Fewer accidents and safer working environment

Higher performance

Better productivity and cost-efficiency

Global expert network

Covering a wide range of equipment and processes

Culture of safety and learning

Higher employee satisfaction and engagement

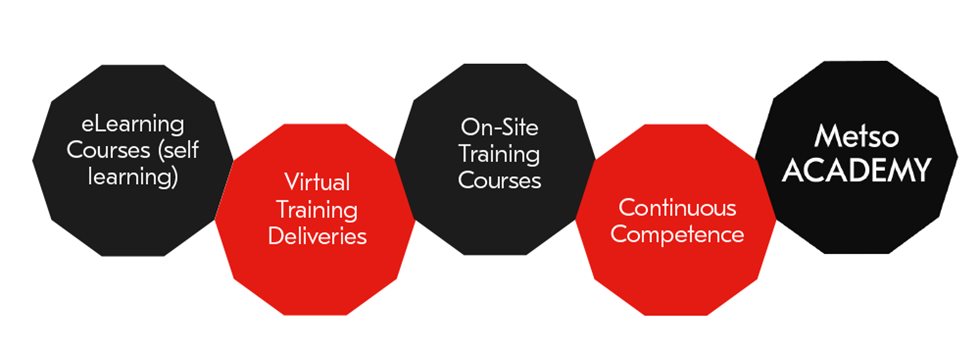

Metso Academy brings together a global team of Technical Training Instructors who are considered subject matter experts in their respective fields. With decades of experience and broad industry knowledge, we can provide high-quality training to your personnel.

Metso Academy can cover everything from theory to practical training, ranging from training on single pieces of equipment to plant-wide solutions. We offer training on-demand and tailor our courses to customer specific machines and processes.

Keep up with today's challenges

Training offering for Mining, Aggregates and Metals refining industries

Safety

Guidelines on safe use of equipment and the relevant safety regulations

Technical overview

Mechanical, instrumentation, electrification, automation, hydraulic and pneumatic overviews

Operational overview

Parameter adjustment and operational overviews

Maintenance and after-sales support

Guidelines on services and performing maintenance in a safe and correct manner

Equipment trainings

Generic Geminex™ OTS

Generic Geminex™ OTS is a dynamic simulation of a generic minerals processing or hydrometallurgical circuit to help understand the use of the equipment and process dynamics with professional training material. This is a great and cost-efficient way for plant operators to learn about individual process areas in hydrometallurgical areas or concentrator plants plants. Generic OTS systems are fast and easy to set up for customers, available online and for a full concentrator and hydrometallurgical plants package.

Plant specific Geminex™ OTS

If a customer wants to take the next step and tailor the simulator training to their exact plant layout, then a plant specific OTS is the great option. It is a dynamic simulation of plant specific processing circuits with realistic Process Control System (PCS) interface to help understand the plant dynamics under variable conditions. Plant operators can practice on a simulation of their own plant and have hands-on experience running their circuits or full plant process in a safe, controlled and risk-free environment. This option requires some pre-work to configure the simulator to match the customers circuit or plant.

Did you know...

Did you know that Metso Academy also certifies our service teams?

Our Services Certification is a structured training program with modules designed for specific technologies targeted for Metso’s employees executing service activities at our customers sites.

It is a multi-level certification increasing in complexity and competency requirements as our personnel progress through the trainings.