While contamination and misalignment would normally be attended to as soon as detected, significant damage caused from these issues would typically happen over a longer time frame of weeks or even months. On the other hand, improper lubrication could cause failure overnight if a single disastrous event were to occur. Indeed, from our experience, improper lubrication or lack thereof has sent more pinions to the scrapyard than any other causes of failure, which is a shame considering the high-quality open gear lubricants available on the market and the relatively straightforward application process, based on known industry standard AGMA 9005 for Industrial Gear Lubrication.

Achieving operational excellence: The importance of proper gear lubrication

Types of lubricants

Choosing the right lubricant is crucial to ensure the operational reliability of a gear. Many different companies have released brands of lube products which can all be grouped into three broad categories, each having different properties and characteristics and requiring a different application method.

Asphaltics

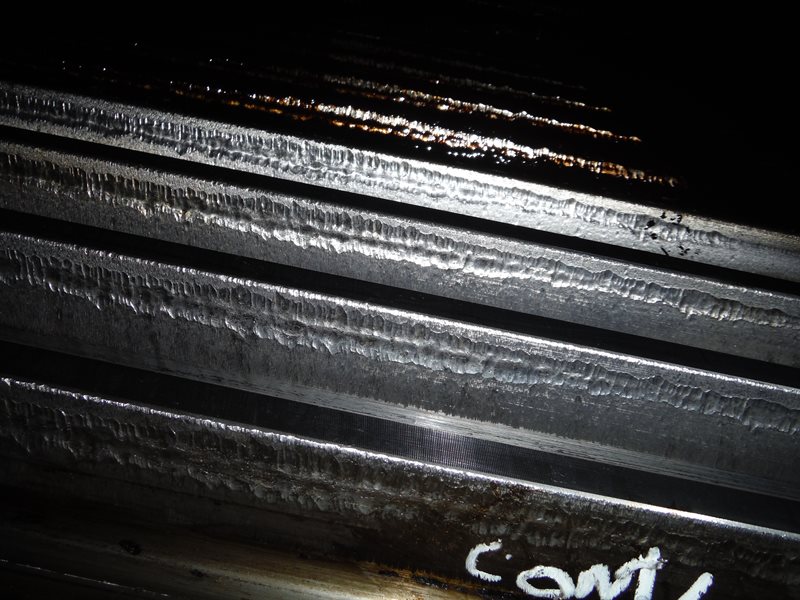

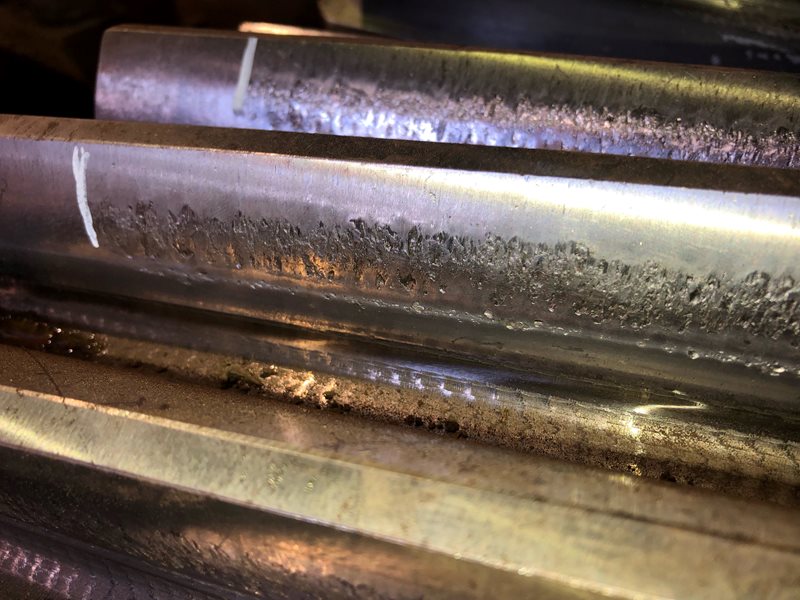

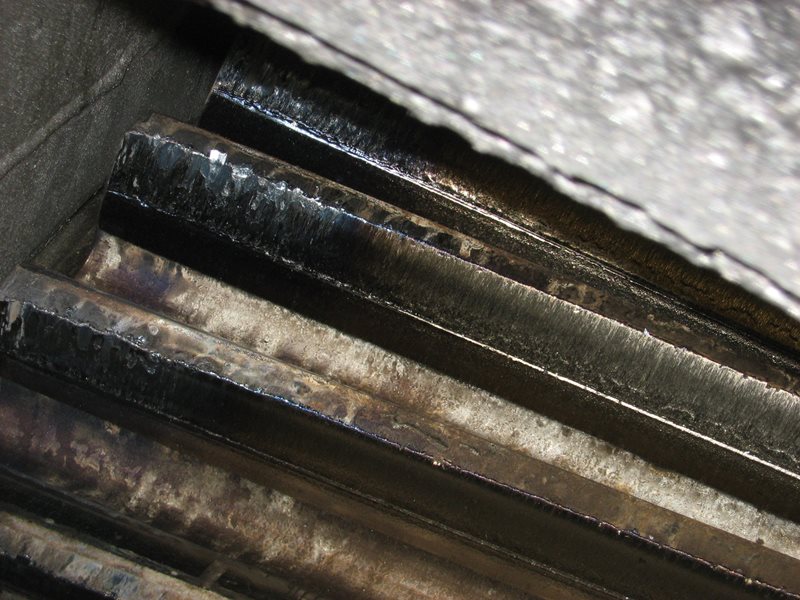

Everyone recalls this dark, thick, and tacky product which has been a long time favorite of mill operators for decades as it has been regarded as “the old reliable”. This opaque substance that sticks to anything and never seems to come off is referred to as Asphaltic, a mixture of residual compounds from the petroleum refining process. Highly viscous and tenacious, diluents are used to aid its pumpability when applied to an operating ring gear using an intermittently applied spray. Hence, longer spray intervals are required for diluents to evaporate to achieve the lubricant’s undiluted viscosity, which then provides the needed oil film to separate the mating surfaces of the gear and pinion.

Oils

This cleaner looking translucent product is also extremely popular throughout the industry with the emergence of engineered synthetic products. Formulated from refined mineral or synthetic oils or a blend of both, these also include anti-wear and anti-scuff (EP) additives. Very much like asphaltics, oil cause an oil film separation between mating surfaces but requires a more frequent application rate due to its less tenacious nature.

Greases

Greases are formulated from lower viscosity mineral or synthetic oils with the addition of thickeners or carriers to hold the base oil in place on the mating surfaces during operation. Fluid films are thinner and application intervals must be short.

Understanding the application to get it right

Tribology experts who study the science of friction, wear, and lubrication may prefer certain products over others while mill operators often have their own preference. Indeed, some prefer the dark sticky nature of Asphaltics that provides visual confirmation that the gear is entirely lubricated while others prefer the more translucent synthetic oils, as it allows for visually easier detection for the presence of wear mechanisms. Whichever the preference, all categories are commonly used for gear lubrication but with slightly different application methods.

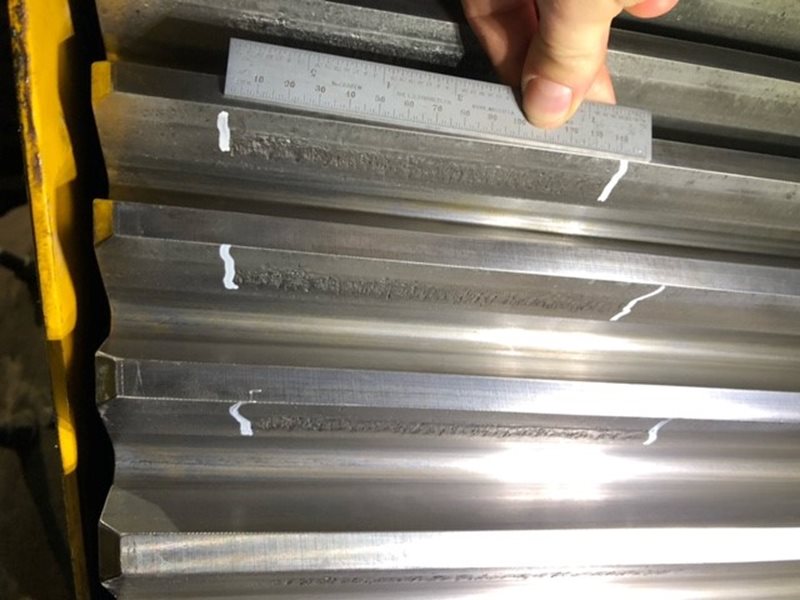

Getting the application right is just as important as selecting the proper lubricant. For grinding mill gears, intermittent spraying of the gear is recommended, and one must keep in mind two key parameters, namely the quantity and frequency of application.

- Quantity of lubricant to be applied to a certain gear is established by AGMA 9005’s Table 10 where the face width and outside diameter determine how much lubricant is to be applied per hour, regardless of lubricant type.

- Frequency to be applied is the interval time between sprays which varies based on the type of lubricant being used. While lube suppliers formulate their own recommendations, the following intervals are typical for each type of lubricant, meaning that the recommended hourly quantity is divided by the number of intervals per hour:

- Asphaltics – 15 to 20 minutes

- Oils – 5 to 15 minutes

- Greases – 2 to 5 minutes

The bottom line is that quantity is determined based on the gear geometry while frequency is determined based on the type of lubricant selected.

Gear Spray System

Typical system arrangement

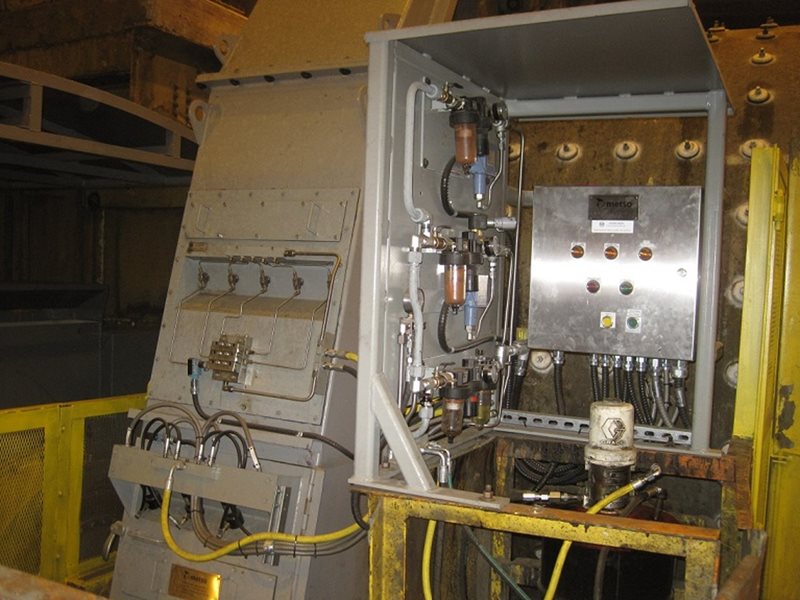

Typical gear spray systems found in grinding mill applications use intermittent spraying. This simple system consists of a lube pump, a divider block with nozzle assembly, two air control panels (one to pump the grease to the block and one to control the spray cycles) and a controller panel. This system could easily be retrofitted to any mill gear arrangement through small modifications to the gear guard.

Making sure it works

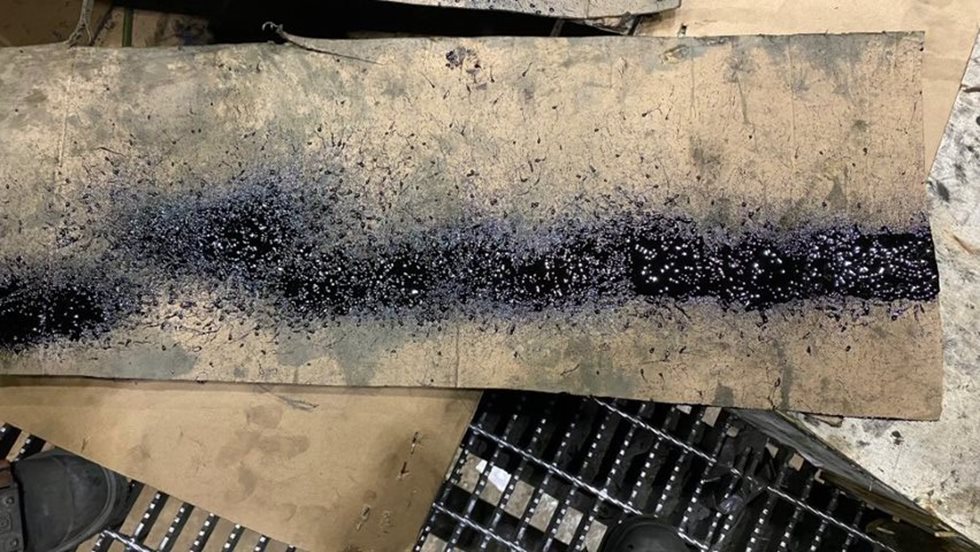

Once installed, the gear spray system requires verification to ensure proper functioning. This verification can be summarized in three simple steps. First, the controller needs to be adjusted to achieve the right number of pulses per spray and sprays per hour. Secondly, a spray pattern check on a piece of cardboard allows the visual verification of whether the nozzles are spraying lubricant evenly across the entire face width. Thirdly, manually verifying the time between sprays with a timer allows for the confirmation that the application intervals are within recommendations for the chosen lubricant.

Failsafes cannot hurt

Like any automated system, adding a failsafe or other systems for redundancy is a great way to eliminate all risks of gear spray failure which could have disastrous consequences on the gear and pinion. A cycle switch could be installed on the controller to send a signal to the mill PLC to trip the clutch or stop the motor if more than two spray cycles are missed. Also, an infrared system could be installed to monitor temperatures across the gear face and send a signal to the mill PLC if temperatures begin to rise unexpectedly which would also cause a mill interlock to prevent damaging the components.

Metso expert solutions bring safety and sustainability benefits

Although many causes of gear and pinion failure exist, improper lubrication is among the most common but could also be easily avoided through the implementation of good operational and maintenance practices. Metso is a provider of expert solutions to ensure the reliability, integrity and longevity of a grinding mill’s most critical component. Through close monitoring with the use of advanced instrumentation, periodic inspections and preventative maintenance services, our service offering can bring significant safety and sustainability benefits to your grinding operation.