Ultrafine screens can be utilized in all mining and minerals processing applications, gravel pits, and in aggregates production. They are ideal for fine wet separation in grinding circuits when the highest separation efficiency is required.

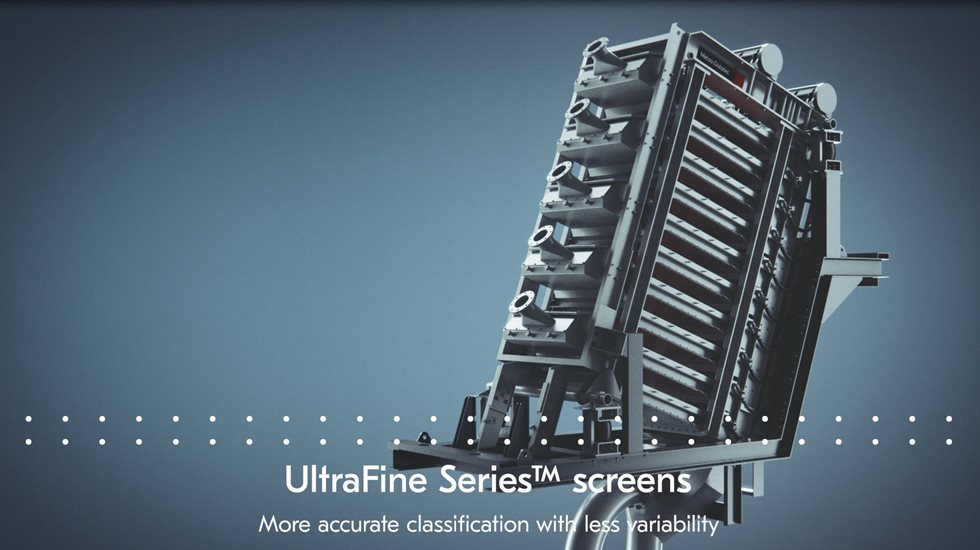

High performance in a compact assembly

Metso UltraFine Screens deliver double the screening area relative to other fine-screening technologies in a much more compact overall assembly. It utilizes a modular design with up to 10 individual screen decks nestled together into a single vibrating assembly.

Accurate feed distribution across the 10 decks is critical, so the unit also incorporates a patent pending feed splitter box to ensure the feed is evenly distributed across the complete width of each screen deck, increasing performance despite the compact size.

Low overall cost

The smaller footprint results in reduced building and infrastructure cost, which greatly reduces the initial capital cost to implement this technology.

Additionally, screening performance is less influenced by plant operational variability and require smaller pumps than hydrocyclones in a similar setup. These, in turn, contribute to better energy efficiency and improved recovery, resulting in a lower operating cost.

Efficient alternative to hydrocyclones

Metso UFS series are ideal for fine wet separation in grinding circuits. In many applications, they provide greater separation and energy efficiency than hydrocyclones.

Ultrafine screens can also be used in conjunction with hydrocyclones in a two-stage classification to form a combination circuit for getting the best balance between cost and efficiency and to maximize the operational return on investment.

A more sustainable choice

Improvements in the downstream processes result in a up to 25% reduction in energy use, an up to 10% reduction of embedded carbon, less pollution and possibly less water usage.

Expert support

Our screening and separation experts support you in setting up and adjusting Metso UltraFine Screens to fit your requirements. Spare and wear parts, as well as maintenance is available through our global network.