The flotation mechanism speed has a direct impact on the metallurgical performance, wear life and energy consumption in the flotation process.

Our experts successfully completed a Speed Optimization Service at Saucito mine to examine the key factors involved in maximizing Ag recovery and improving energy consumption.

About the mine/customer

The Fresnillo, Saucito mine is one of the Group’s most important operations, with a contribution of 32% to total silver production in 2018 which generated 21.9% of total adjusted revenue for the leading precious metals group in Mexico. The underground silver mine was commissioned in 2011 with a mining capacity of 7,800 tpd/2,600,000 tpy.

History

Outotec and Saucito mine have been working together for several years, supplying and servicing mining equipment. The gradual depletion of higher ore grade areas has resulted in the mine having to implement initiatives to improve operations. We have been working side-by-side with Saucito mine in order to assist in maximizing their performance on the flotation circuit.

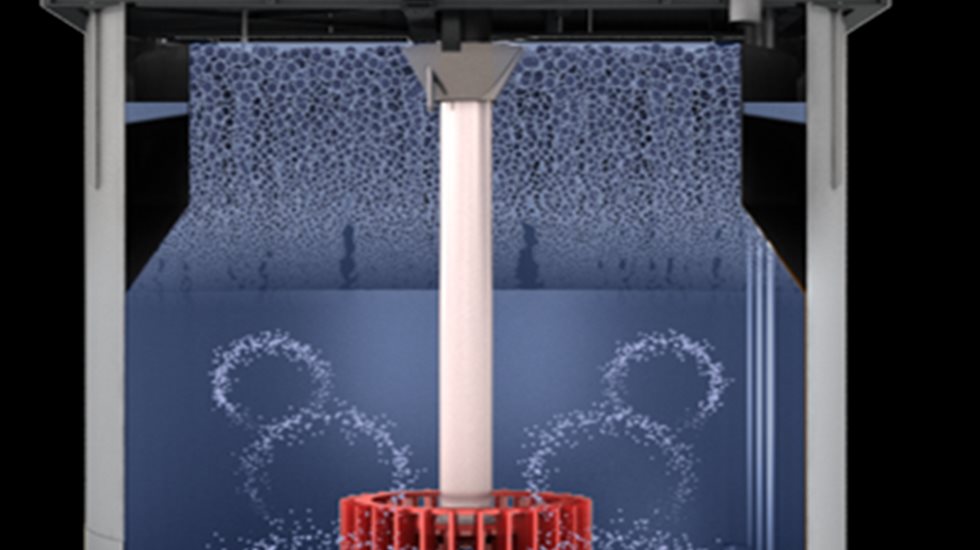

In December 2019 we conducted a FloatForce rotor speed optimization study on the first Pb rougher cell. Sampling campaigns were conducted at different rotor speeds and airflow rates to determinate the ideal conditions that would allow maximized Ag recovery.

Objectives

- Maximize Ag recovery in rougher Pb concentrate

- Minimize Zn & Fe values in rougher Pb circuit

- Study airflow and rotation speed responses in the circuit

Solution plan

- Ore’s response study (2 days)

- Design of experiments (1 day)

- Sampling campaign (3 days)

- HSC® Chemistry mass balancing (4 days)

- Optimizer simulation (2 days)

Saucito mine proactively supported with:

- Ensuring safety throughout the whole Service

- Sample preparation and chemical assays

- VFD Installation in the designated Outotec TC-100

- Site arrangement, information sharing