Why choose Metso grinding mill parts?

Applying the strictest standards and tolerances for guaranteed safety and reliability

Over 100 years of experience designing and supplying hard-working equipment and parts

With 150 distribution centers worldwide, we supply parts where and when you need them

From original to third party to installation, we can support any equipment type

Metso has a proven history of designing, manufacturing, and servicing grinding mills and components. Our extensive range of global expertise allows us to be a flexible service partner for mill sustainability. We can fulfill standard and customized parts and component orders for:

- Heads

- Shells

- Gears and pinions

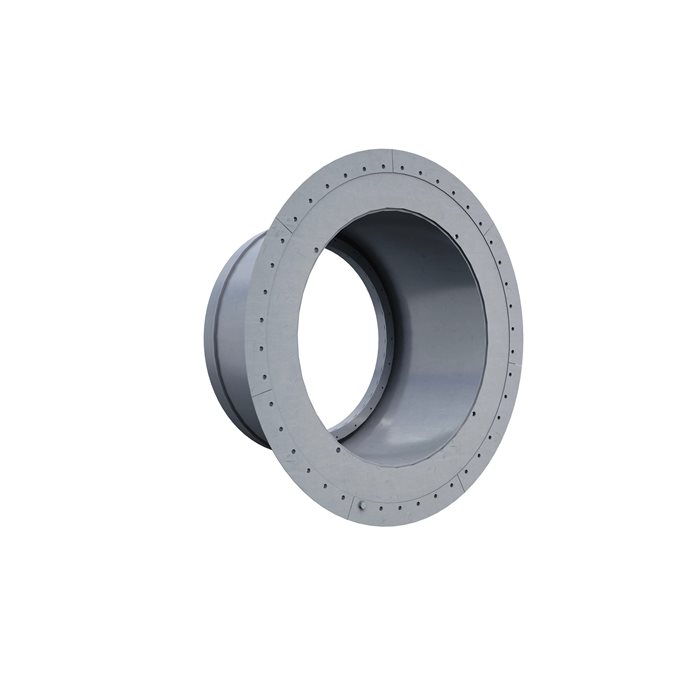

- Main bearings

- Trunnions

- Trunnion liners

- And more!

Material: cast ductile iron or cast steel

Design standard: Metso FEA

Segments: one, two, three, or four

Type: feed/discharge, fixed/floating, integral with the trunnion

Material: fabricated steel (welded)

Design standard: Metso FEA

Sections: integral, two or three cans

Segments: one, two, or three-piece

Material: cast ductile iron, cast steel, fabricated steel

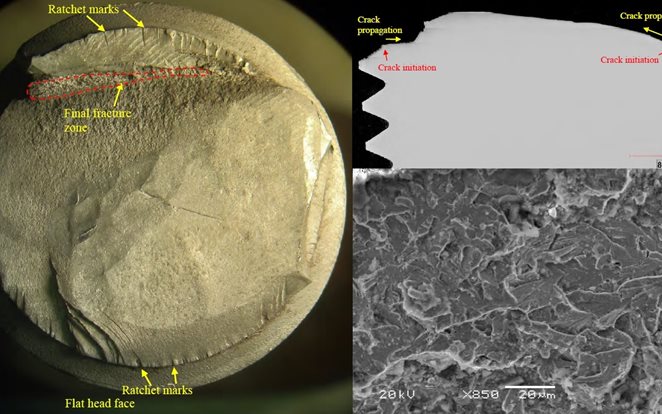

Design standard: AGMA 6014 for open gearing

Section structure: T or Y design

Segments: two-piece or four-piece gears

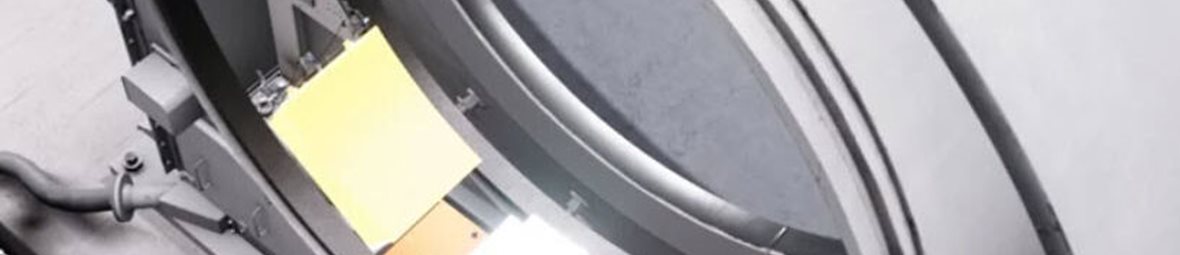

Upgrade options: drop-in pinion assembly, gear guard and components, gear spray infrared monitoring system

Our gear and pinion services include:

- Gear flushing and cleaning

- Grinding mill inspection packages

- Digital girth gear inspections

- Gear set replacement

- Design upgrades for increased production

- Installation and reversal

- Alignment services

- Pinion condition monitoring

- Lubrication systems

Read more about our complete gear and pinion services here>>

Material: fabricated steel (welded)

Type: hydrostatic or hydrodynamic (sleeve/pad), fixed or floating

Design standard: Metso FEA

Upgrade options: bearing insert (bronze, babbitt), seals, temperature monitoring systems, lubrication unit

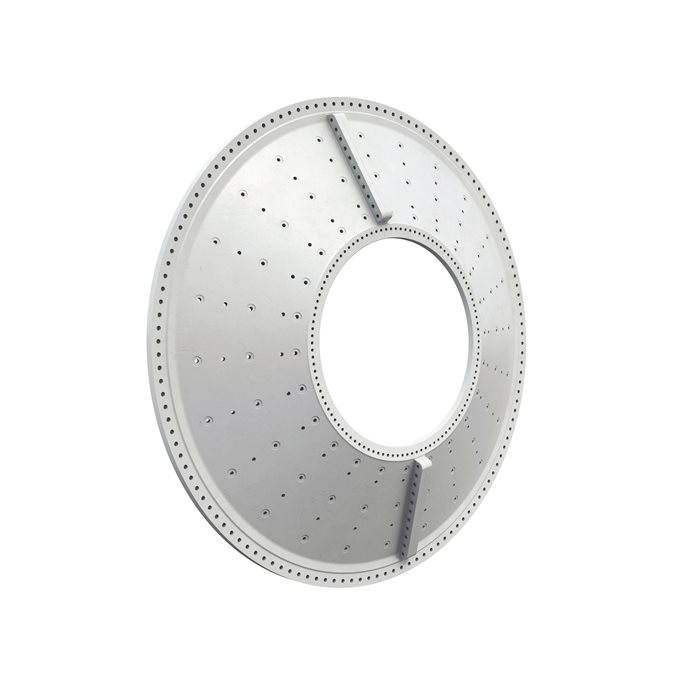

Material: cast ductile iron

Design standard: Metso FEA

Type: feed or discharge, fixed or floating

Material: cast iron or fabricated steel

Wear material: vulcanized rubber lined or lifter and plate style replaceable bolt in

Type: feed or discharge

Learn more about Metso's grinding mill liners >

Specialized hardware

Don't risk it – extend it

Optimizing your mill parts

Many brands, many applications

{{decodeHtmlEntities(field.label)}} |

|---|