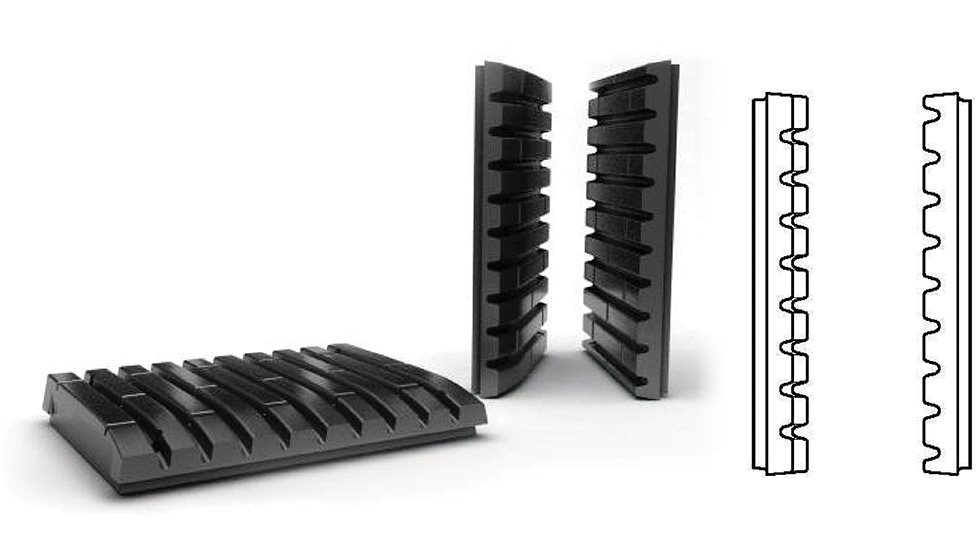

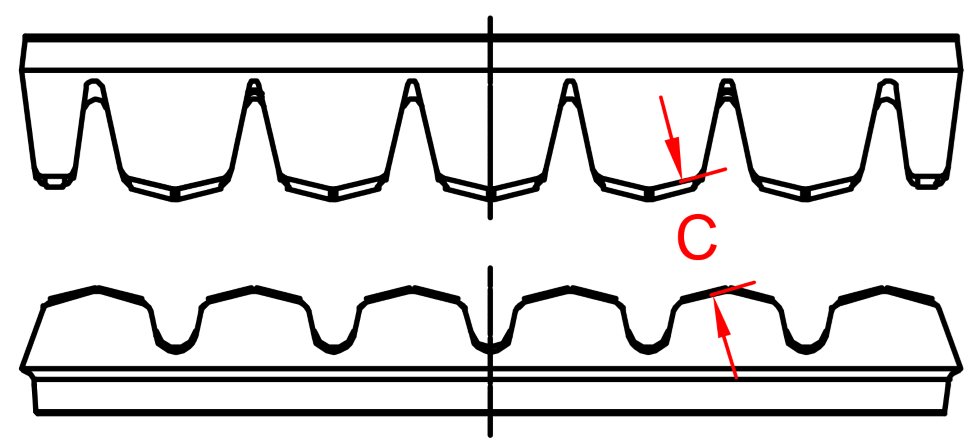

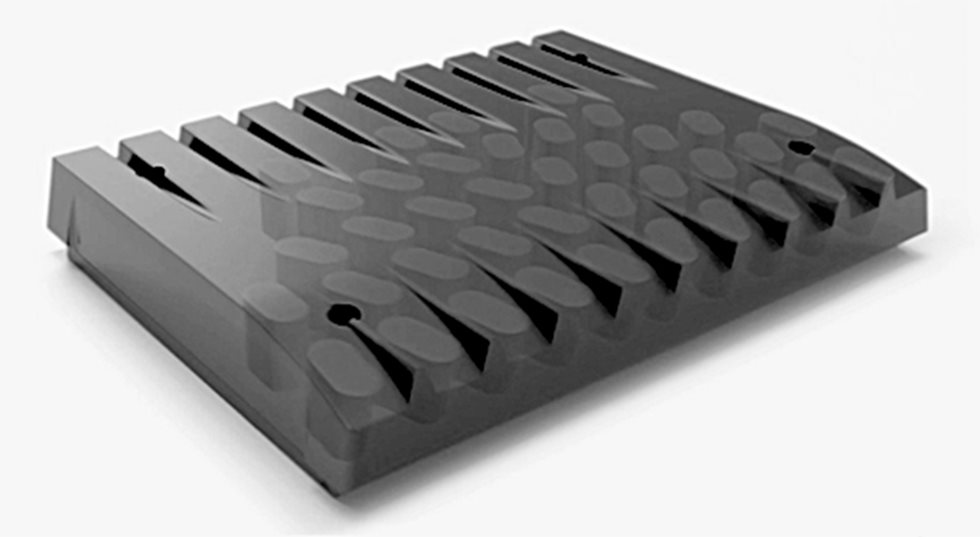

The Quarry profile has a flat-tooth design and plenty of manganese surface area to crush with. It is an all-rounder, and we actually have two versions of it, normal thickness and increased thickness, aptly called Quarry thick, which slightly reduces the maximum feed opening and maximum closed side setting (CSS).

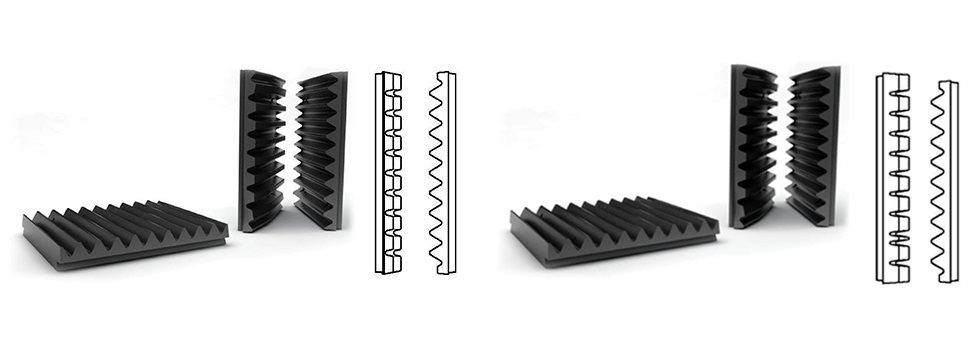

Changing from the Quarry profile to something else can at first seem daunting, as Metso has so many profiles available for the perfect application fit. But worry not. Let’s take a look at the offering and walk through the main profiles and see how they differ from Quarry.

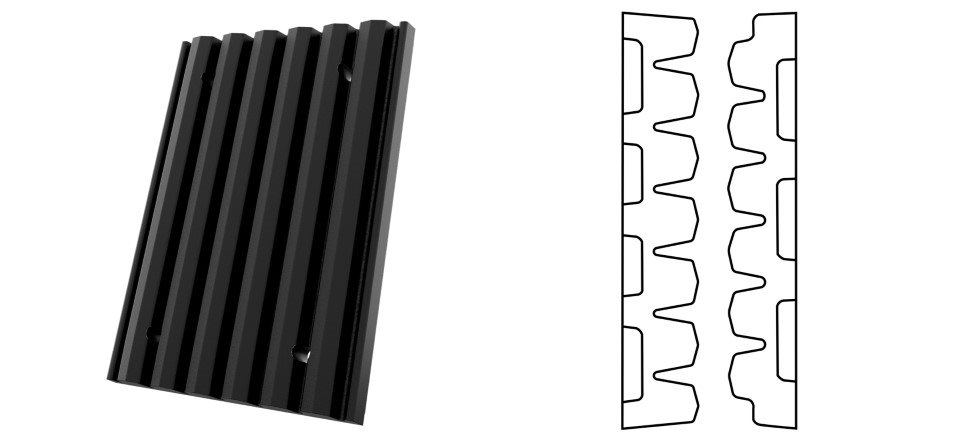

The first stop is the Quarry fixed jaw + Super grip movable jaw combination chamber. Let’s start easy by changing just the movable jaw. Why? Because the fixed jaw die typically wears out faster than the movable. So having the Quarry profile with its flat tooth attached to the front frame of the crusher can still be a good idea.