Customer Challenges

An important aspect of any aggregates plant is to keep the producing assets running, as well as reducing unplanned down time. It is also vital to meet the sustainability regulations and standards while still producing better quality materials. Improving capacity, process fit or extending the machine life by replacing obsolete components or equipment is an ideal way to optimize productivity. Using retrofits or modernizations can also bring production gains to older assets.

Asset upgrade services

In many cases, upgrades are crucial to maintain and improve the performance and availability of equipment during its life span. Asset upgrade services are designed around sustainable products and innovations that allow customers to keep their equipment running as needed. Asset upgrade services are divided into three different sub-categories based on the customer targets, values, and demands.

- Asset care: Offering to maintain equipment performance and availability. This includes everything from maintenance parts and tools to latest design replacements of the most critical parts of the equipment. It is important to consider these basic offers and make sure that all the needed parts are in place before considering more costly alternatives. Ensuring that having the proper kits with the right components needed for maintenance intervals and service stops are available can make a huge difference in keeping your machines running.

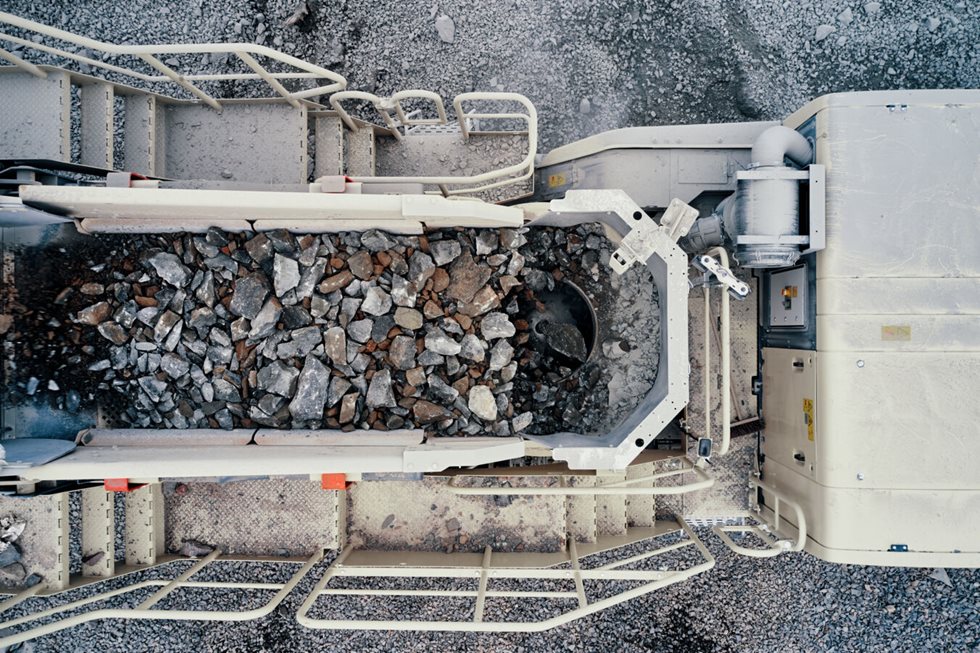

- Asset boost: Sometimes you need more than just the basics. What if conditions are extremely harsh and dusty, leading to maintenance issues for your crushers and screens? Or you may need to significantly improve your final produced product or improve capacity? At this point, it is important to consider options that are easy to order and install, including upgrades and retrofits. Specific services such as by-pass filtering provide improved oil quality and system reliability. Retrofits such as dust filters and debris removal solutions can boost the performance of your machines with a relatively small investment. Another way to drive gains from your assets is by leveraging the knowledge of your site personnel. Upgrading their expertise in regards to the equipment they operate and maintain can help secure additional gains.

- Asset improve: At a certain point, specific assets need to be evaluated to see if larger upgrades are needed to reach your site goals. It is important to balance your goals versus the investment needed to achieve them. Advanced upgrades and retrofits to secure flexibility and process fit throughout the asset life can include crusher and screen upgrades, mobile equipment upgrades, automation and electrification upgrades, or crusher and screen replacements. Though these require a more significant capital investment, the gains can often pay for themselves in certain cases.