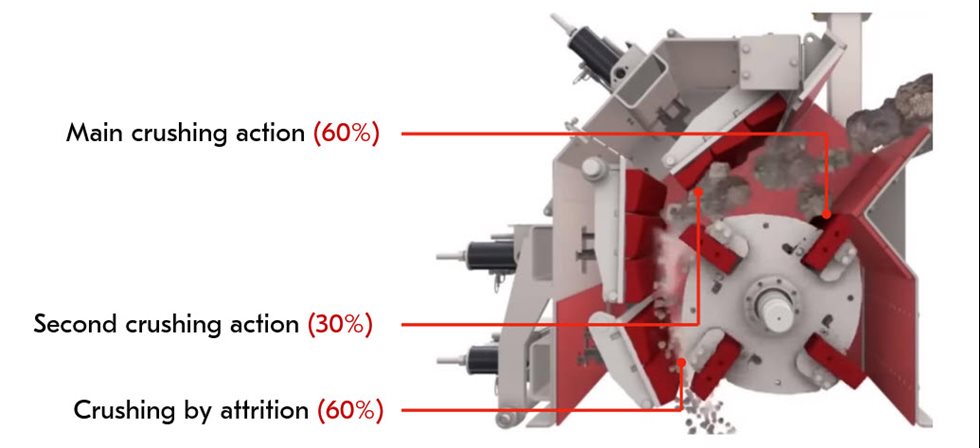

The crushing principle of a horizontal shaft impact crusher

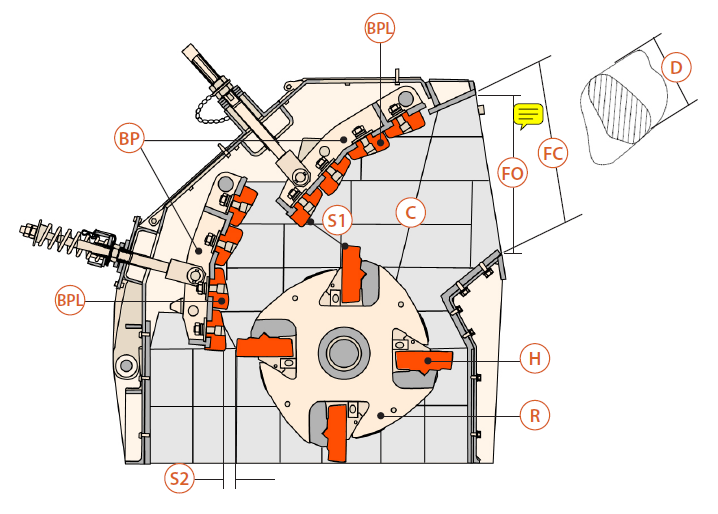

Materials inside an impact crusher, are reduced in size by their impact on the rotor, the impact on the breaker plates and the impact among materials.

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Materials inside an impact crusher, are reduced in size by their impact on the rotor, the impact on the breaker plates and the impact among materials.

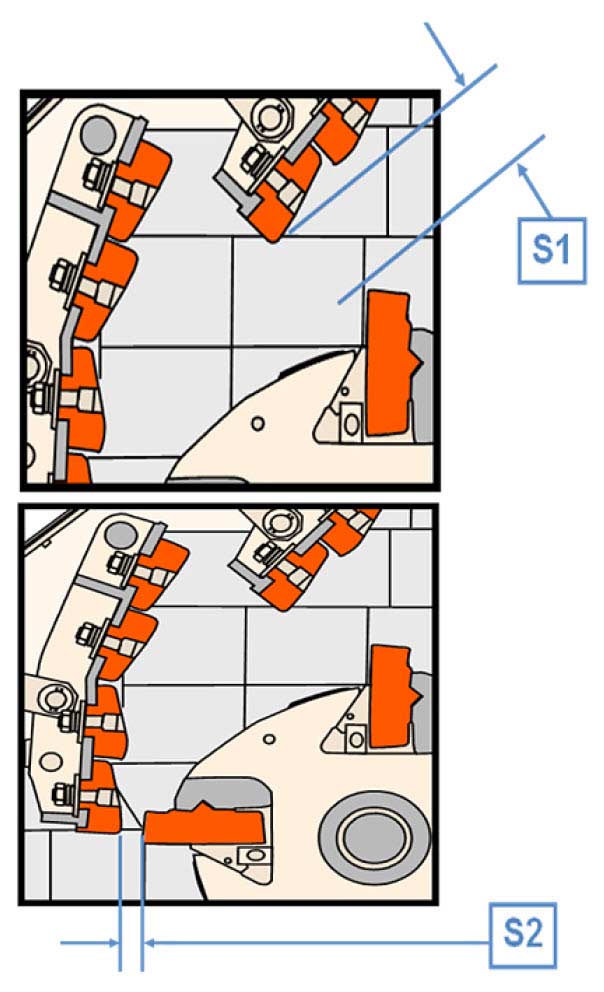

The setting of the last breaker plate defines the crusher setting. It also defines the product size.

The setting corresponds to the minimum distance between breaker plate liner and blow bar.

Crusher settings have to be defined according to the application type, feed materials and required product after the crusher.

Once S2 has been defined, a rule of thumb can be used to define S1

Feeding : 60/600 (F100)

Setting S2 on a NP1415 impact crusher : 20 mm (see table below)

Calculated setting S1 : (600 + 20) / 4 + 25 = 180 mm

The value should not be less than the data given in below table! These values are for reference only however, the minimum setting is related to the application.

{{decodeHtmlEntities(field.label)}} |

|---|

Think about it! The blow bar lifting tool supplied with the machine allows you to carry out maintenance operations with greater security

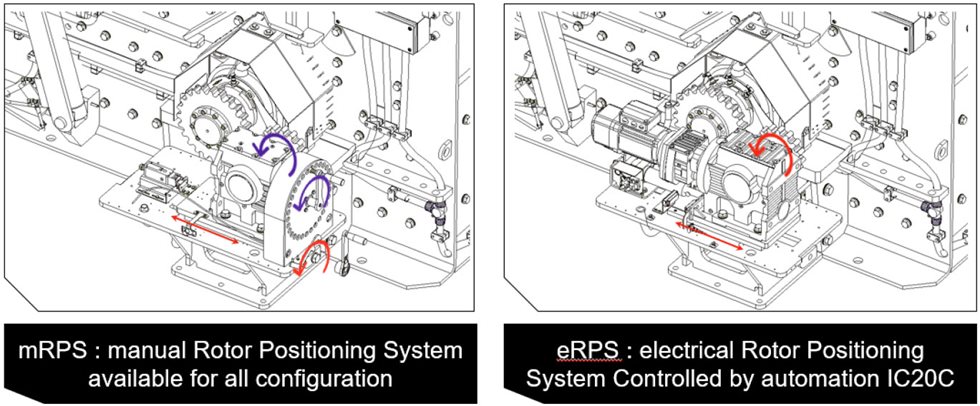

The RPS has been designed to rotate slowly and lock the shaft line for maintenance operation such as blow bar replacement and setting adjustment.

The RPS system is available in two versions:

RPS is EN1009 standard compliant and now mandatory in Europe.