To ensure the suitability of the liner profile for its application, it is important that there is data on which to base your decisions. Here we go through five things that should be defined and why. Get optimum capacity and maximum wear life of wear parts by considering these points from the perspective of your circuit and production. None of these points on its own should be the rationale for choosing the liner.

-

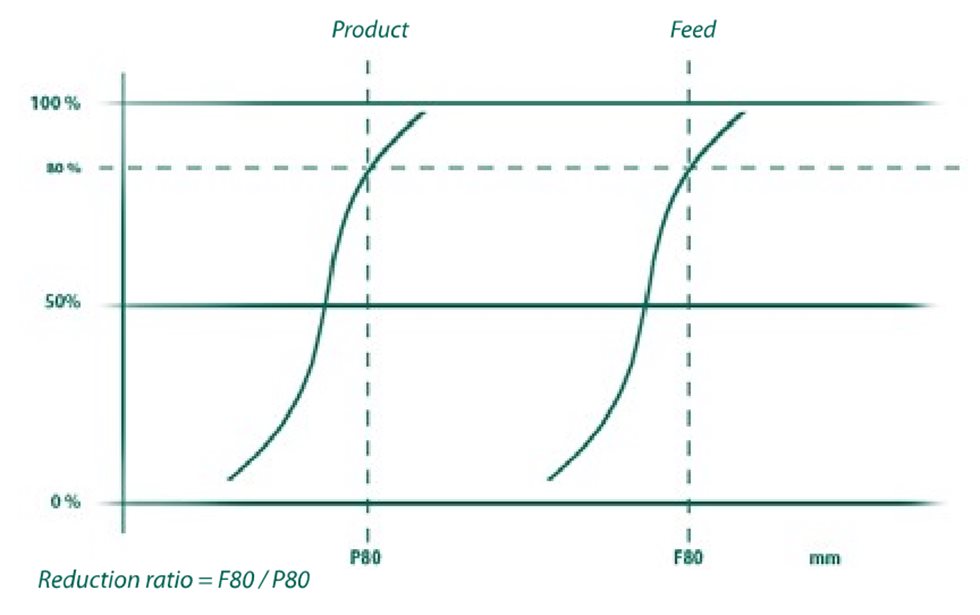

Feed grading

Feed should always be well graded with no gaps in the size distribution, which generally means an even distribution of different-sized feed material up to the defined maximum size. Fines (for example, 0–4 mm) should be screened out before the material is fed to the crusher as the fines may cause packing: this is a force overload and can be seen as adjustment ring movement. There are differences within different product ranges, and Nordberg GP Secondary cone crushers, for example, can handle a certain amount of fines in the feed due to their steep vertical cavity and adjustable stroke length.

As a rule of thumb:

- Oversize feed material decreases capacity and can cause abnormal wear of the liners.

- Too small feed size for the cavity increases the wear of the bottom part of the liners and may cause poor utilization of the wear parts.