We further invested in optimizing design, engineering, project execution, and supply base to reduce pellet cost per ton for smaller plants. As a result, Metso now offers competitive basis pellet plants with smaller size and production capacity, incorporating all the experience and process features of the world's biggest and most efficient plants.

|

Compact-sized pellet plant key features

|

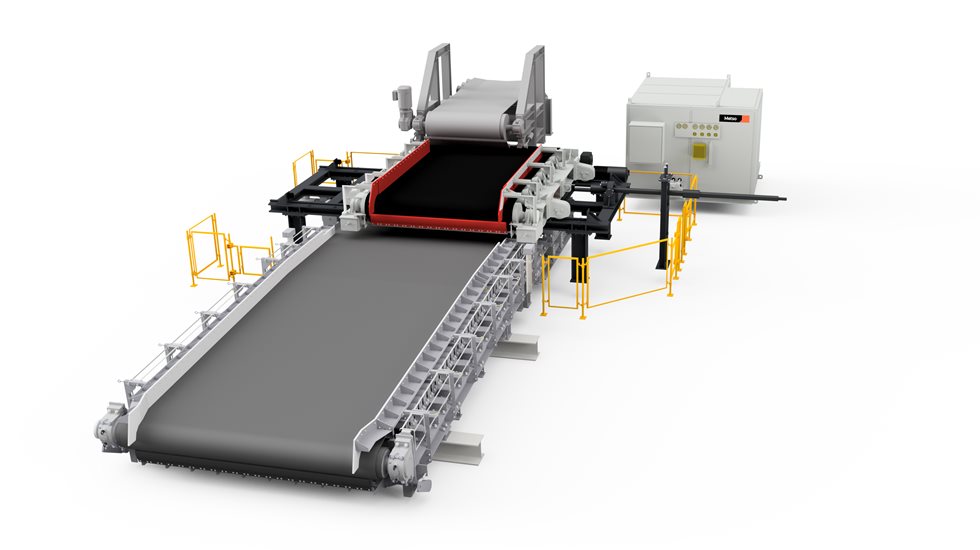

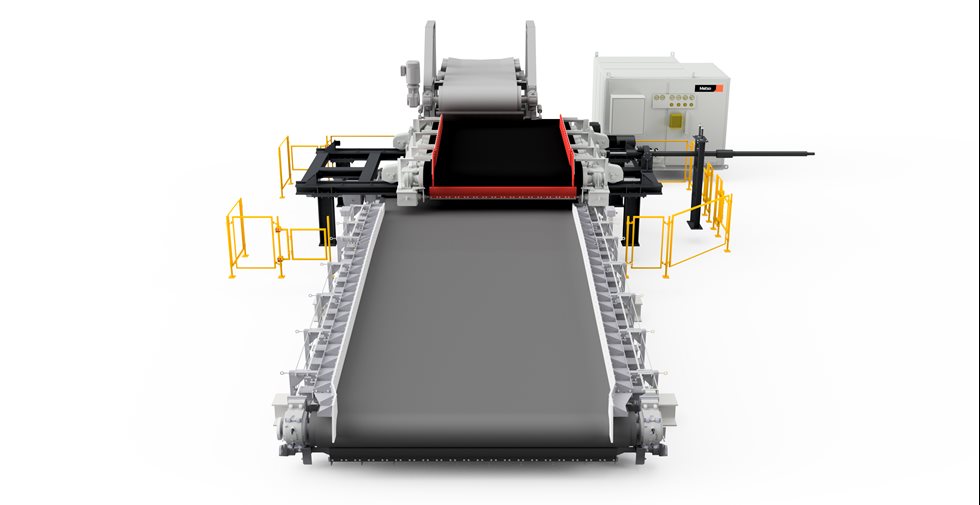

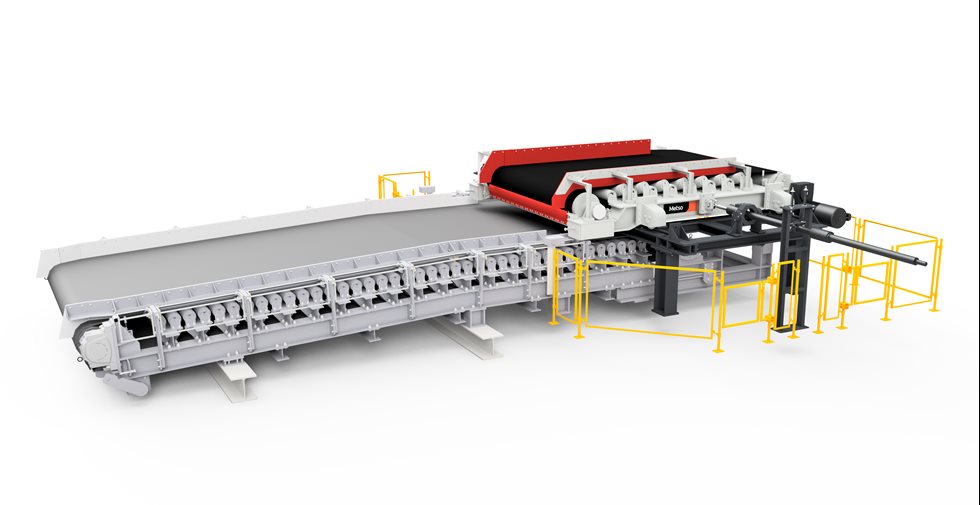

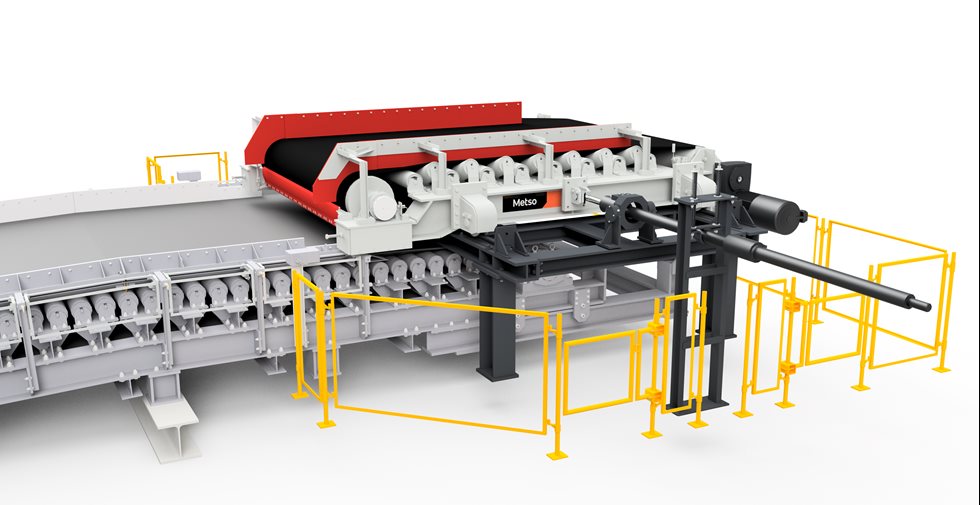

Our proprietary design for key equipment ensures efficiency, reliability and longevity for the process. And now, we take pride in displaying our latest product: the Shuttling Spreader Conveyor. It is specifically developed to serve our Compact-sized pellet plants and caters to the in-line arrangement of 3m pellet plant, as opposed to the L-shaped arrangement seen often in larger 4m pellet plants.