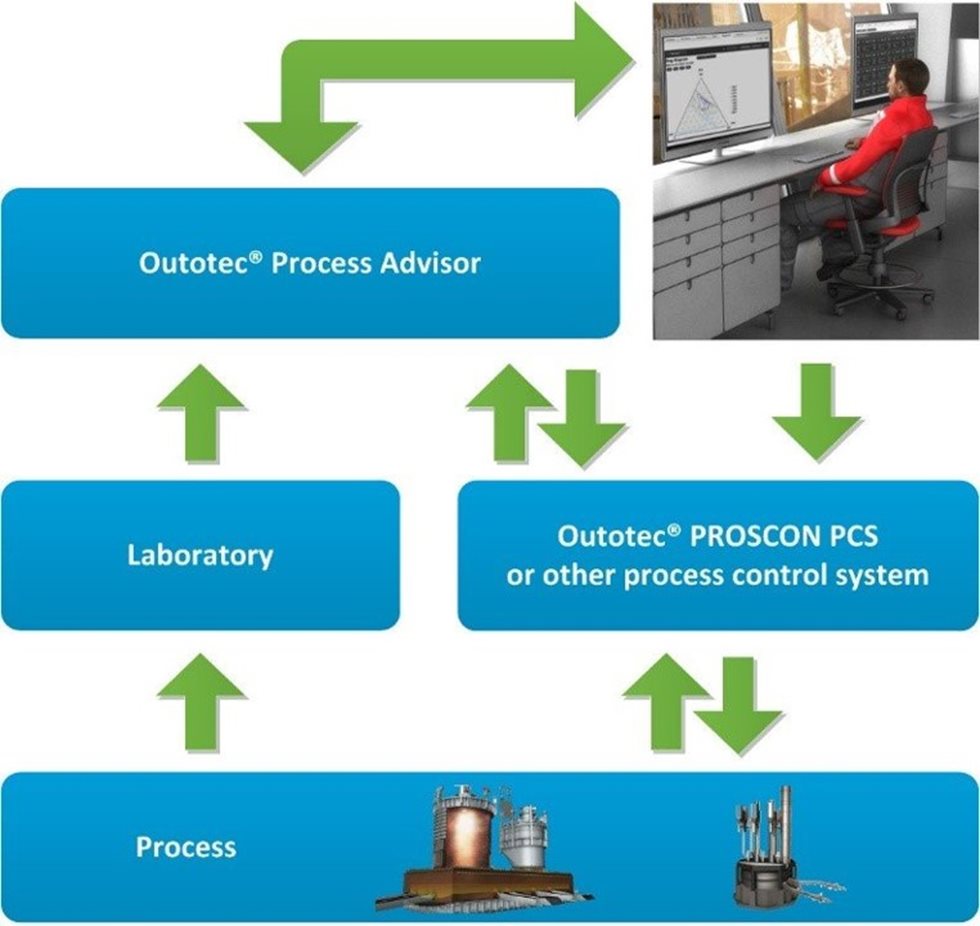

The software contains tables for feed mixture, matte/blister/metal and slag assays and melt temperatures. These can be directly linked to receive the values through an OPC link or they can also be manually entered in the Process Advisor. The Process Advisor can be installed as an operator advisor tool or as a fully closed loop system.

Process improvements

The Process Advisor is based on first principle models, meaning that thermodynamics and physics are modelled as accurately as possible. This means that even weak correlations found from further data analysis can in many cases be interpreted as physical model paramaters and thus it is easy to tune without the risk that the change causes any upsets in other part of the model. This is in contrast to pure statistical models, which are based on earlier correlations which do not necessarily describe the actual physical situation in an obvious way, i.e. the correlations are more difficult to interpret and incorporate. Additionally statistical models are very sensitive to changed conditions, which take the model outside of the initial data set. Part of the service agreement for the Process Advisor is to keep track of any correlation, which can be interpreted as physically relevant, and tune the Process Advisor model accordingly (case 1).

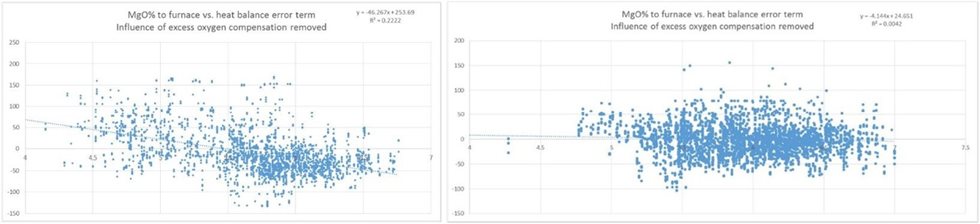

Case 1: Optimizing MgO mineralogy

A change in concentrate mineralogy was experienced in 2016 and a correlation was found showing that the MgO% in the feed material influenced the heat balance of the furnace more than the model accounted for. This was physically interpreted so that the mineralogy of MgO was more complex than assumed in the model. The new mineralogy was updated to the model and the correlation disappeared, which meant that the feedforward input to the online heat balance improved and the heat balance control works now stably regardless of the feed material’s MgO content. The following pictures show the correlations before and after the tuning.