The absence of a high-speed revolving mass or any continuously moving parts makes plant construction and machine maintenance simple. Pressure filters also consume less fresh water, use a lot less energy and provide a much higher starch recovery than centrifugal separators.

Larox® pressure filters can be applied to the following processing of starch from the following raw ingredients:

- Corn (Maize)

- Potato

- Rice

- Tapioca (Cassava)

- Wheat

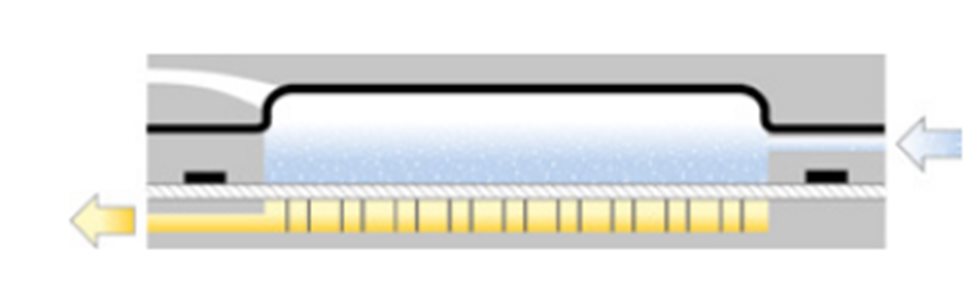

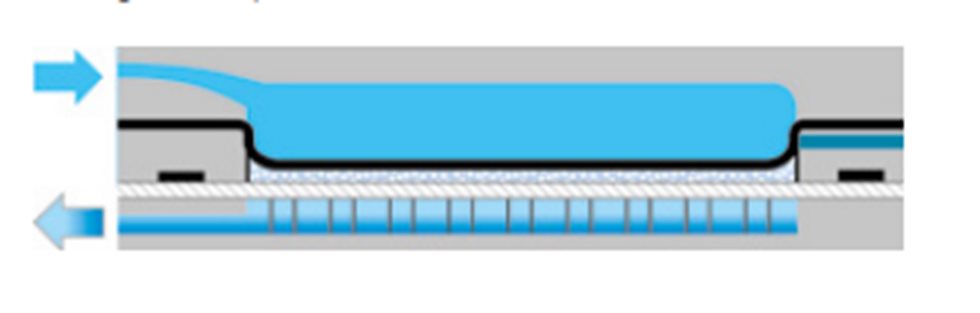

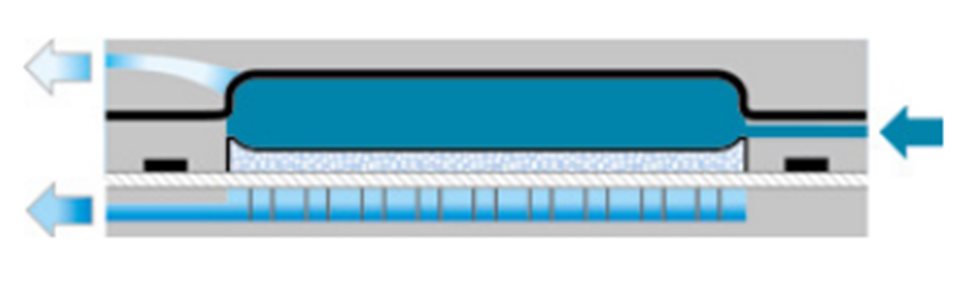

Automatic pressure filters such as Larox® PF filter, process starch suspensions as follows:

Feeding

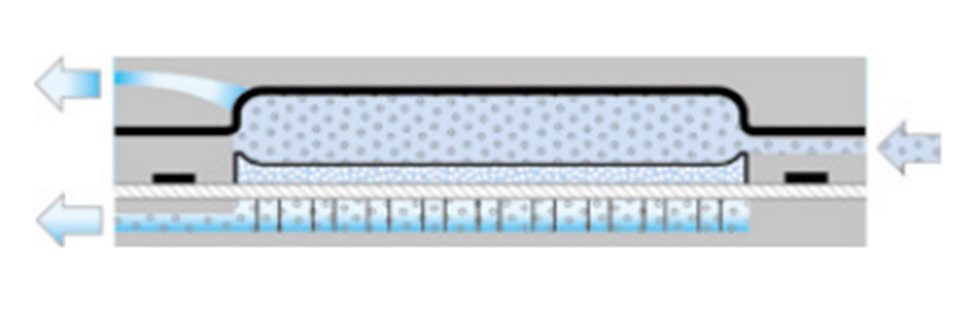

When the plate pack is closed, a set of chambers is formed and starch suspension enters these through feeding pipes. A filter cake builds up and filtrate passes through the filter cloth, support grid, and filtrate hoses. Because the cake is static and horizontal, it is extremely uniform and there are no misaligned forces to either deform it or cause cracks to form within it.