Two solutions to consider for preventing dropped charge

1. Proper start-up procedure

Having and following a proper start-up procedure is key to avoiding a dropped charge. After a prolonged shutdown, it is not advisable to jump-start a mill. If the mill is equipped with an inching drive, rotating the mill slowly will ensure the breakup of the frozen charge. If an inching drive is not available (typically in the case of older or smaller mills), then intermittent start-stops can be used until the charge starts tumbling.

2. Metso Outotec Locked Charge Detector

A second way to avoid a locked charge is by installing a patented Locked Charge Detector which basically measures mill acceleration and aborts the startup if locked charge conditions exist.

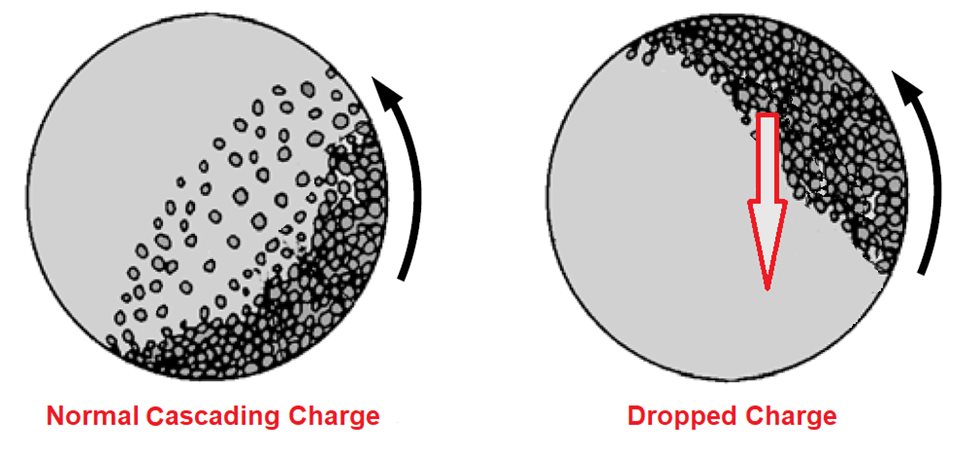

The Locked Charge Detector is used to disengage the mill clutch if a locked charge condition is detected during start-up. The system uses an encoder mounted on the pinion shaft to measure the velocity as the mill rotates between 40 and 70 degrees. By measuring the rate of change of velocity (acceleration), the device will detect whether the charge has cascaded in this zone. If the charge has not cascaded in this zone, the detector will send a signal to disengage the clutch to stop the mill from rotating. The mill must stop rotating when a locked charge is detected to prevent the charge from being lifted and dropped.

The Locked Charge Detector is mainly controlled from the main control room. A local PanelView display is located nearby the mill. From the control room, the operator is able to see the status of the LCD system, enable/disable the LCD system and reset a fault condition.

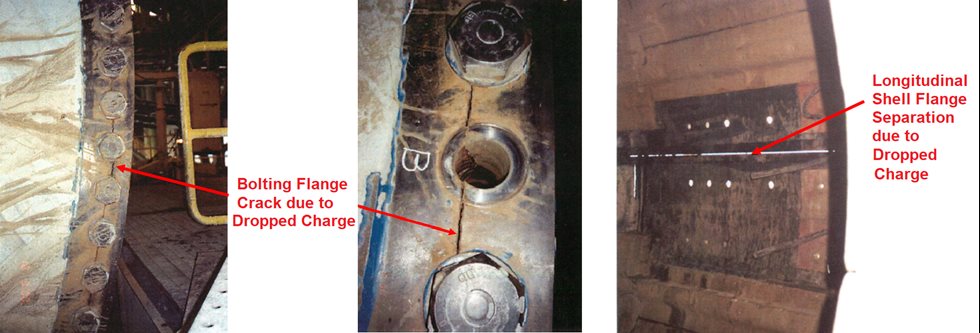

Preventive maintenance is the key

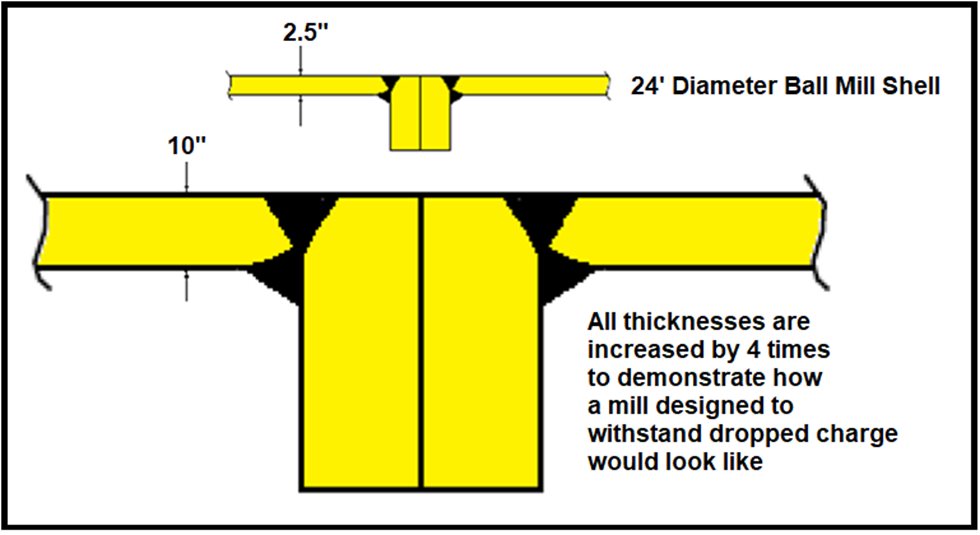

The effects from dropped charge can damage your mill and, in some cases, bring your production to a halt if the damage is severe enough. Taking the time to implement either of the above solutions may mean some additional effort and planning up front but should be considered as an integral part of a plant’s overall preventive maintenance strategy in order to minimize unplanned mill stoppages.