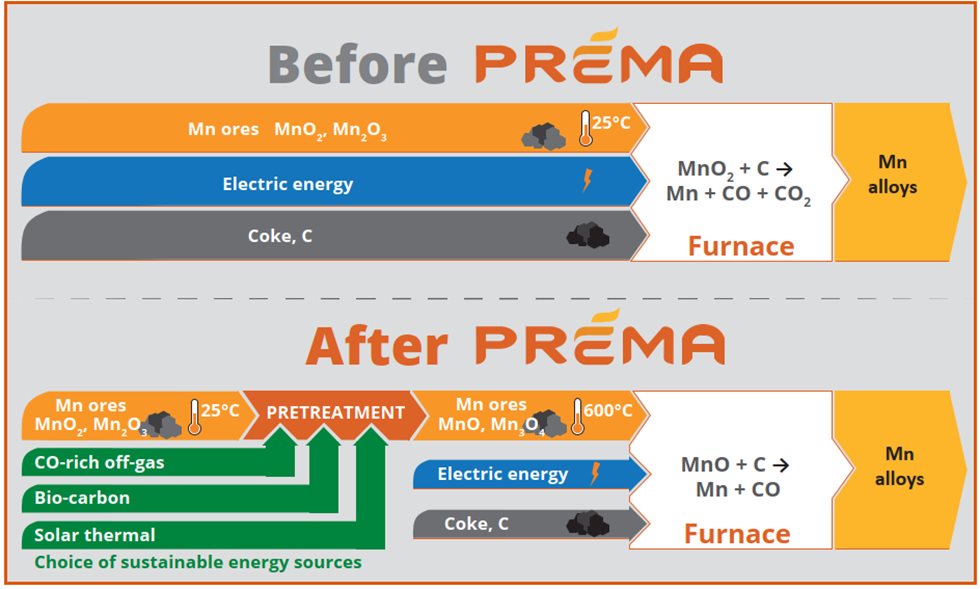

Integrating the novel PREMA pretreatment technologies in the process, currently used by smelters, will lead to more flexibility regarding the use of raw materials and has ambitious targets:

30% more potential for reducing energy and carbon consumption

25% less primary energy used and 15% less CO2 emissions

20% less fossil carbon consumption

10% less electrical energy used

10% lower operating costs for global Mn ores processing

Regarding rotary kilns, these ambitious targets have to be confirmed with pilot tests and HSC Sim data, a Metso Outotec proprietary process modelling tool. As the global manganese alloy production required 12 200 GWh of energy and created around 14.2 million tons of CO2 emissions in 2017, PREMA has the potential to significantly contribute to the reduction of energy consumption and CO2 emissions in the manganese alloy industry.

Metso Outotec has been leading the work package Pilot testing and engineering of manganese ore pretreatment technology”. The task of this work package is theidentification and pilot testing of the most promising preheating and prereduction technology options to increase energy flexibility and CO2 emission reduction, taking into account different furnace set ups, properties of the input material and site-specific conditions related to the availability of energy sources/carriers.

Project partners include manganese alloy producers like Eramet and FerroGlobe, and research organizations like Sintef in Norway, DLR in Germany and Mintek in South Africa. As the main technology partner in the project, Metso Outotec has been responsible for selecting the suitable pretreating technology (fluidized bed, shaft furnace or rotary kiln), conducting analysis of the reduction behavior of the manganese ore from different sources and determining the optimum operation window for the rotary kiln option.

The project is scheduled to be finalized in March 2023. “With this new application for the rotary kiln, Metso Outotec aims to achieve the sustainability targets that we, as a brand, are committed to.”