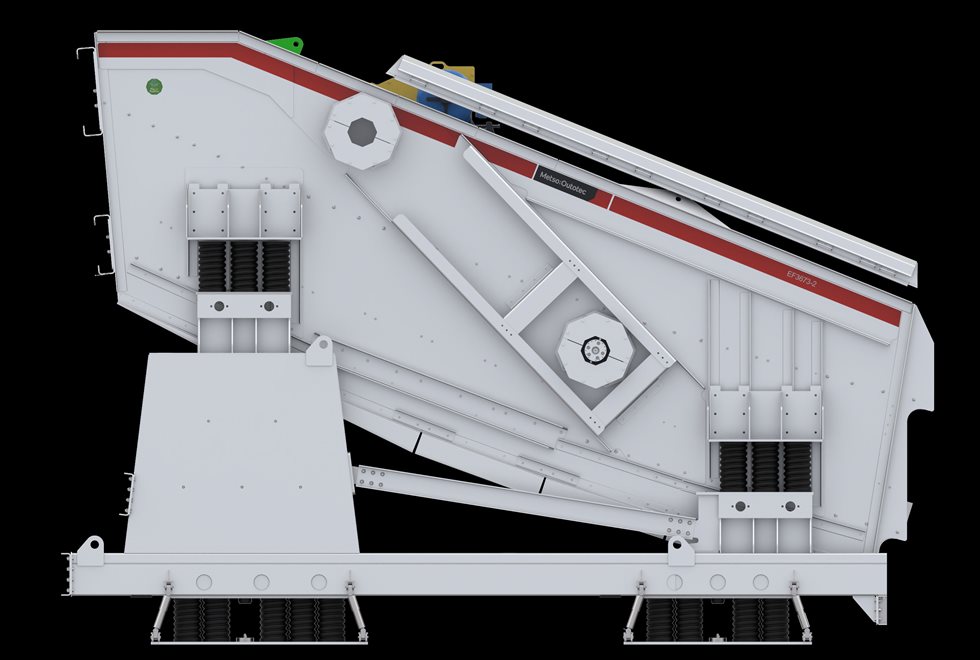

Safety is a top priority for Metso Outotec and for our customers. We are constantly striving to develop new reliable solutions to help our customers reach their targets. The unique to screening but familiar mechanism design, combined with the self-synchronized elliptical motion of a banana screen, and with our fully monitored control system enables 6G acceleration in normal operation, safely and more reliably than any equivalent banana screen. The new elliptical motion screens will be globally launched at the end of 2022.

Safety benefit 1: Minimal exciter/mechanism maintenance with no changeouts

The mechanism design allows us to increase force output over a typical roller bearing exciter or mechanism, while keeping maintenance to a minimum. There are no roller bearings! Theoretically, our unique solution means infinite bearing life and it is expected to outlast screen service life. Moreover, the new screen has a maintenance-free intermediate shaft and an easy oil change remote lubrication system, with a high-capacity, heating, cooling and onboard filtering system.