Safety

Although safety does not form part of the OEE framework, safety is of utmost importance to us. Our QEHS Management System defines the principles and elements by which conducts its global business to protect its employees and stakeholders, the public, company property, and the environment. Our filtration training equips participants with the knowledge and skills required for the safe and efficient operation and maintenance of Larox filtration systems. Training is delivered by our experienced team of in-house experts and covers both basic knowledge of filtration systems and Larox technology, as well as advanced training on optimal operation, maintenance, automation, and troubleshooting.

Regular, systematic inspections by our trained experts provide you with a clear understanding of the current condition and maintenance needs of your equipment, including future spare parts requirements and safety-related information. This information assists in planning and decision-making regarding long-term resource, maintenance, and production schedules that can maximize uptime. The Outotec Equipment Inspection service provides you with clear data and expert recommendations that help to improve decision-making, keeping your operations running like clockwork.

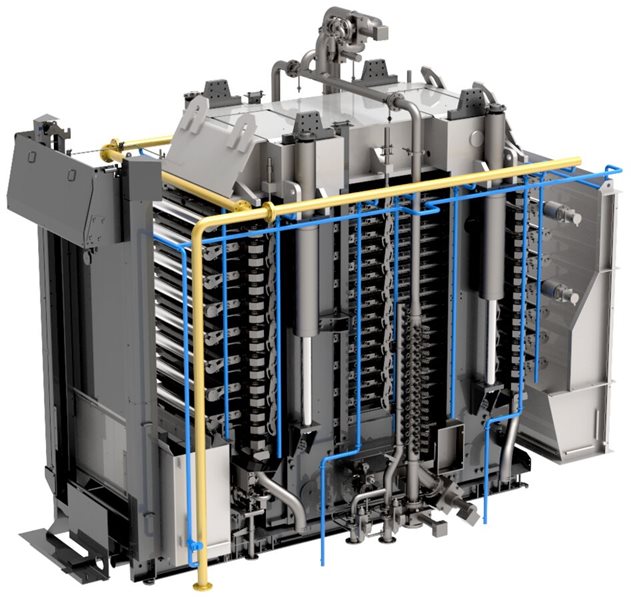

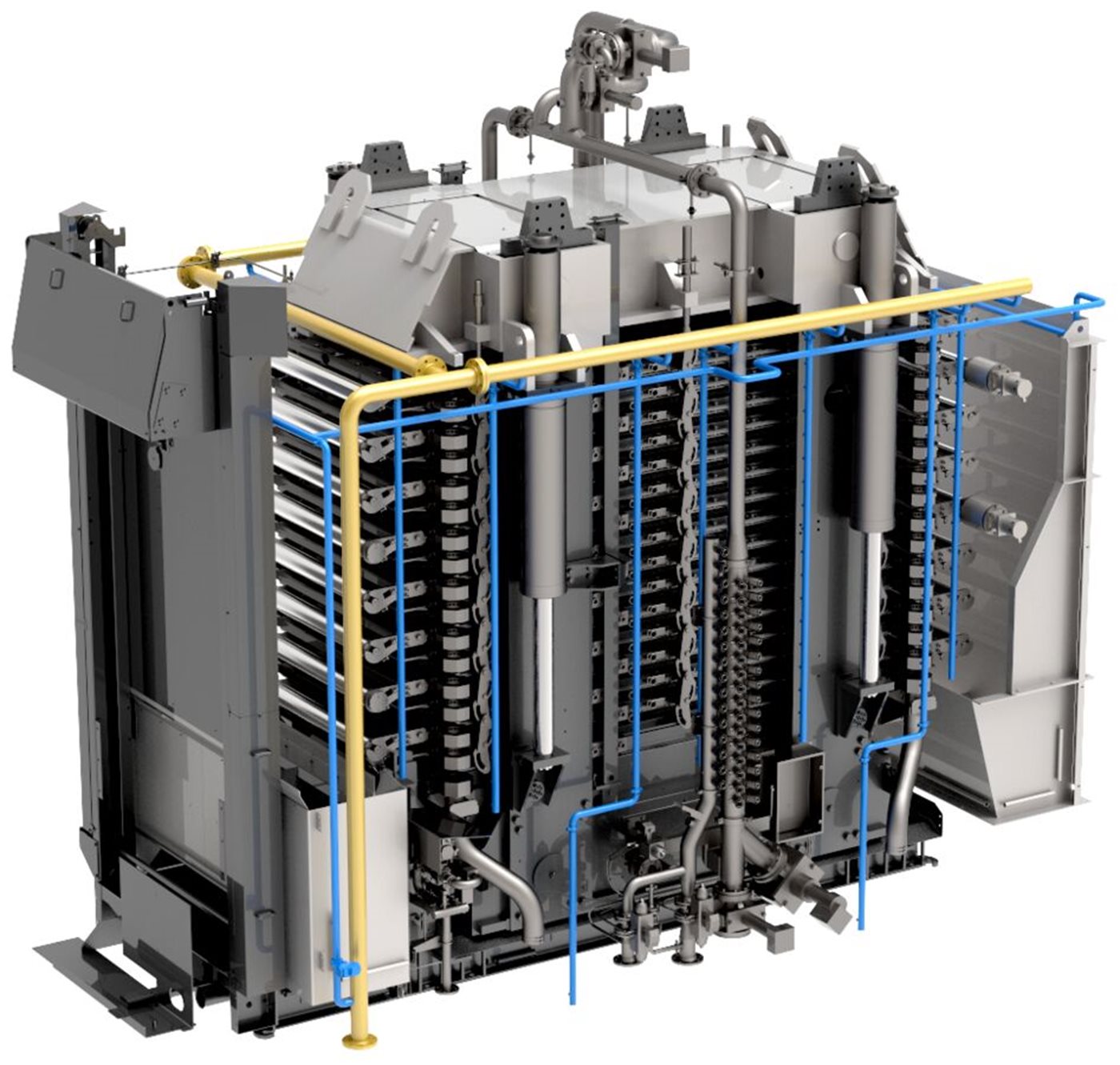

The efficiency of your process equipment is a critical factor in maximizing your operational profitability. If you are operating aging equipment, you face a difficult choice between investing significant capital in new equipment or modernizing your existing equipment. Our filtration experts will work in close partnership with you to design the most suitable modernization solution for your plant and operations.

Our Service platforms include in-built maintenance scaffolding which improves access to the plate pack during maintenance operations. The Pressing Air valve upgrade has additional safety features to combat unexpected chamber pressurization during maintenance.

For more information regarding how our maintenance and service products can improve your filter safety, please contact your local representative and request more information.

Larox PF Filter Services