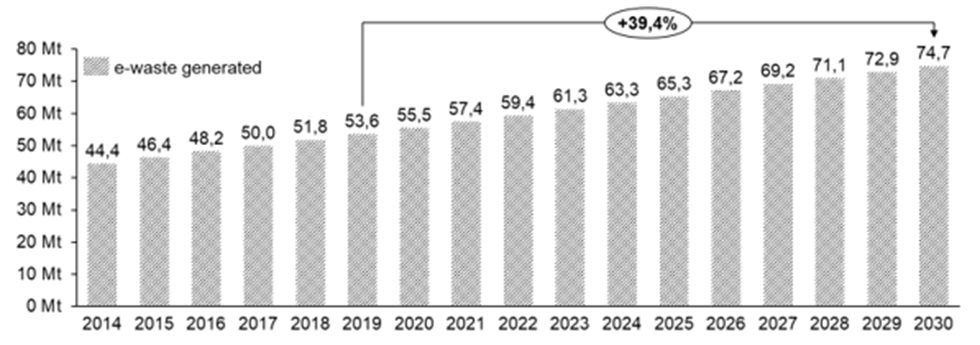

In 2019, approximately 53.6 million metric tons (Mt) of e-waste was generated - an average of 7.3 kg per capita. It is estimated that the amount of e-waste generated will exceed 74Mt in 2030, meaning that the global quantity of e-waste is increasing almost 2 Mt per year.

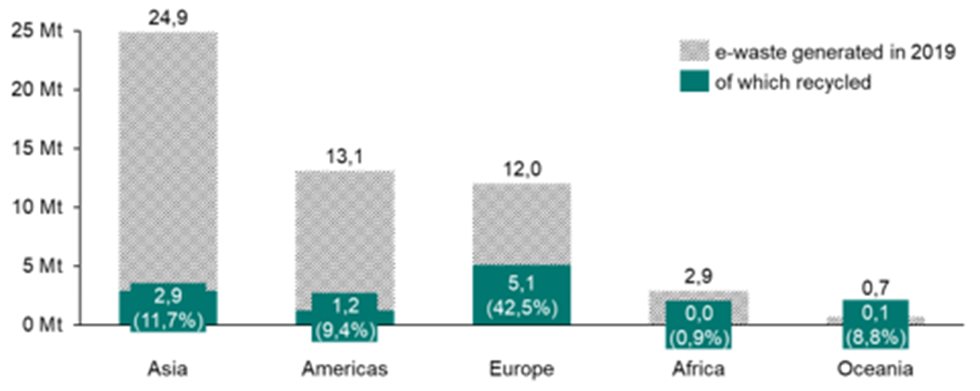

The increasing amount of e-waste is driven by higher consumption of electronics, urbanization, industrialization, short life cycles and limited repair options. In 2019, the highest quantity of e-waste was generated in Asia (24.9 Mt), followed by the Americas (13.1 Mt) and Europe (12 Mt), while Africa and Oceania generated 2.9 Mt and 0.7 Mt, respectively. In terms of e-waste generated per capita, Europe ranked first (16.2 kg per capita), followed by Oceania (16.2 kg per capita) and Americas (13.3 kg per capita), and finally Asia and Africa at just 5.6 and 2.5 kg per capita, respectively.