Variations in lift-off compromise the sensitivity of the inspection probe, leading to inconsistent data collection throughout the inspection process. This lack of consistency hinders repeatability in subsequent inspections, making it difficult to identify trends.

Our extensive experience using the Cleansolv cleaning program for over 20 years in implementing a rigorous gear cleaning program underscores its efficiency, taking less than an hour to clean a girth and pinion. This program, in conjunction with ASTM E2905 guidelines, ensures optimal conditions for subsequent inspections.

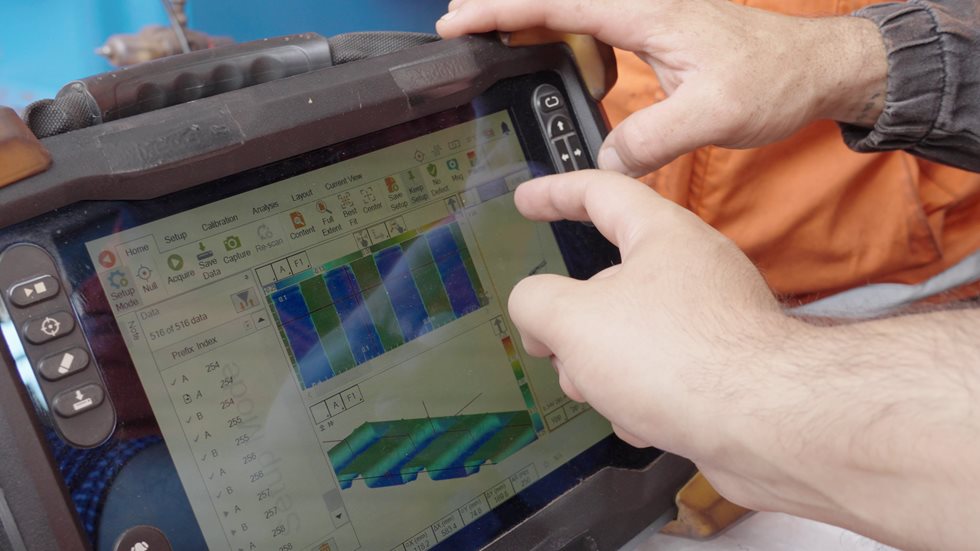

The superior capabilities of DGI, operating at higher frequencies, provide unparalleled 100% coverage of critical gear areas such as the addendum and dedendum, and root all in one pass across the gear flank. This surpasses the limitations of Alternating Current Field Measurement (ACFM) and Phased Array Ultrasonics (PAUT), allowing for more comprehensive inspections.