Its core business expanded over time to include a rental and transport company that operates beyond regional borders. In 2017, Bierbrauer & Sohn continued to add to its portfolio with the acquisition of basalt and lava plant Terratec-Basalt GmbH.

With a history of taking on demanding application challenges, Bierbrauer & Sohn is now considered Germany’s largest operator of Metso Outotec mobile crushing and screening plants. Over the past few years, between 35 and 40 Lokotracks® are said to have been used at the Kretz depot and the nearby quarry.

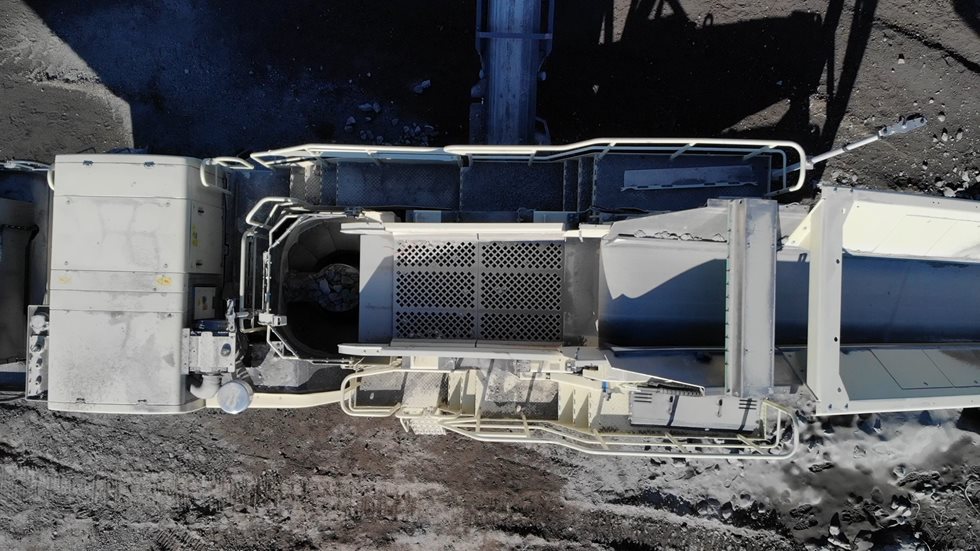

A successful entrepreneur charged with improving operating efficiency and cost-effectiveness in the face of rising fuel prices, Managing Director Karl-Werner Bierbrauer recently became aware of Metso Outotec’s newest Lokotrack® LT220GP™ mobile cone crusher. Together with Metso Outotec's long-standing supplier and service partner for technologies, Fischer-Jung Aufbereitungstechnik GmbH, it was decided to visit the new machine directly at the Finnish factory in Tampere. After a successful presentation, Bierbrauer decided to use the plant at his quarry in Ettringen, making it the first LT220GP™ delivery in Europe. Fischer-Jung has already been working exclusively for Bierbrauer's group of companies for ten years.