“Earlier, we purchased and transported the aggregates for our cement mixing plant from a site 50 kilometers away. With the ST4.8, we are able to produce aggregates right next to our cement plant, saving us a lot in transportation costs and aggregate purchases,” says Constantin Apreotesei, owner of Ecoservice Srl, summarizing some of the benefits resulting from the Lokotrack ST4.8.

Ecoservice Srl is a mid-sized construction company located in northeastern Romania, some 350 km from the capital, Bucharest. The company is a significant employer and one of the few Romanian enterprises in the industry to have entered recycling. Metso’s Lokotrack ST4.8 is their first mobile screen. With it, they’ve already produced washed aggregates for their cement plant and have recycled concrete and bricks.

The company operates a fleet of trucks, excavators, wheel loaders and other construction equipment. They also own a workshop for steel fabrications and other assemblies.

Wanted: A multitasking screen

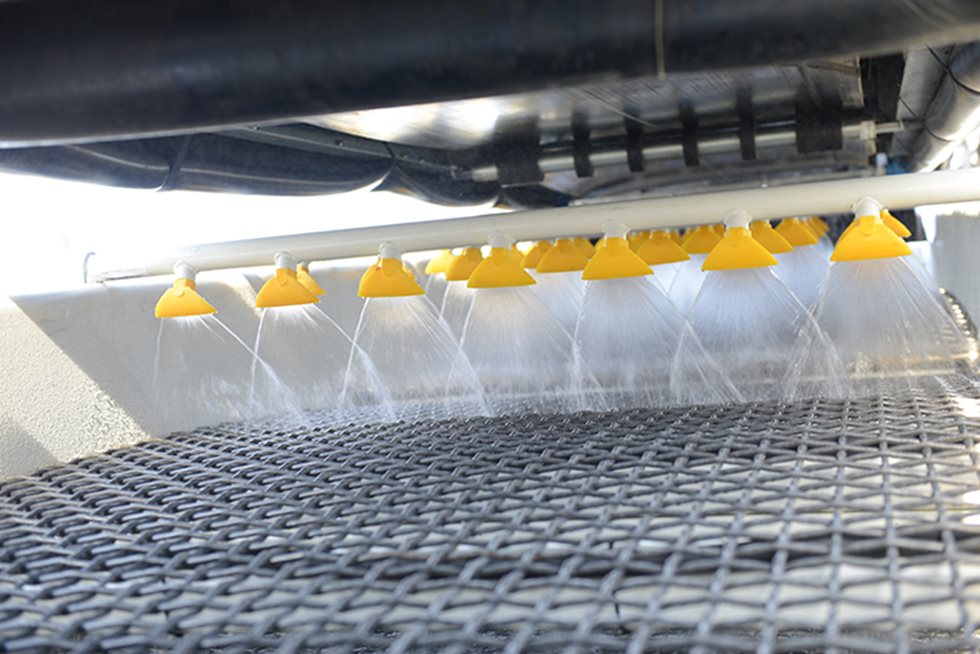

In order to save in transportation costs, Ecoservice wanted to expand its fleet to include a screen. This way they could produce the aggregates they needed on site instead of buying and hauling them. The company knew they needed a mobile screen suitable for both wet and dry screening and for aggregates and recycling applications. Additionally, the equipment had to be easy and safe to operate and environmentally friendly.

They decided to approach Metso. At that time, Metso’s offering didn’t include a suitable track-mounted product off the shelf. However, because Metso has delivered numerous washing screens on wheels and for stationary plants, the necessary know-how was there.