In November 2021, Jean-Marc Fonzé contacted Jean-Philippe Rezette from BiA, a dealer for Carriére des Limites' quarrying plant, to discuss alternatives for their previous sand tertiary impact crusher. They were frustrated with its dust generation, lack of production volume, and flexibility.

Business was good at Carriere des Limites Rochefort quarry in Belgium´s Ardennes reqion and the limestone quarry has been producing nearly two million tonnes aggregates and sand per year. But the inefficiencies of its impact crusher had the potential to harm the supply of high-quality manufactured sand to their majority ready-mixed concrete-producing clients.

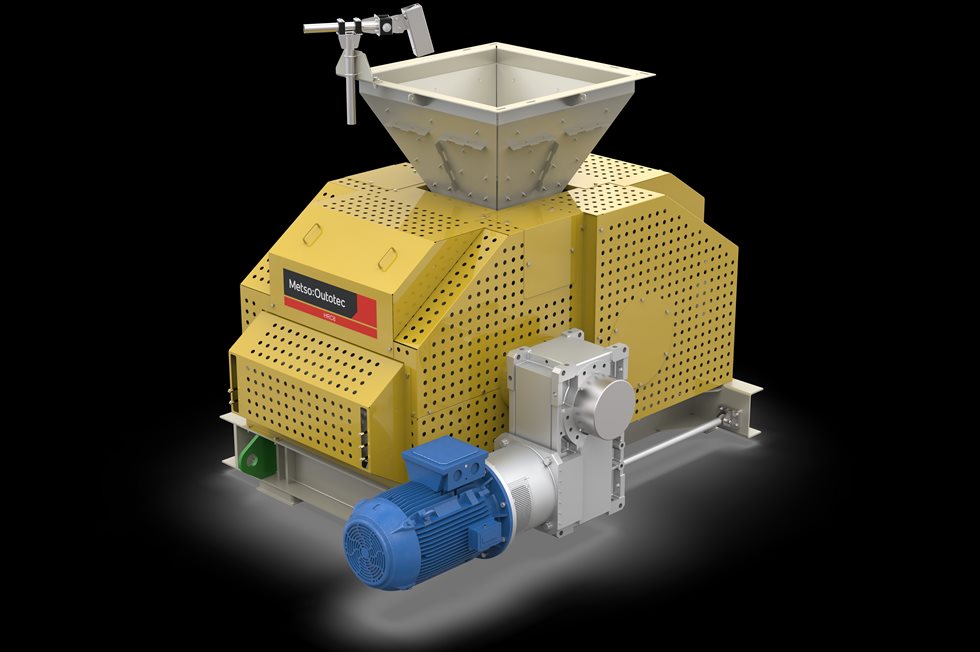

BiA had previously supplied Carriére des Limites with six Nordberg and Metso-branded primary and secondary crushers for the company’s limestone-aggregate-product production, and Rezette knew Metso had just launched the HRC 8 high-pressure roll crusher. He got in touch with Oldemar Meneses, Metso’s manager of impactor and sand solutions, based at the company’s Mâcon, eastern France facility. He and arranged Meneses to visit Carriére des Limites to discuss the potential benefits of deploying an HRC 8 plant at the Rochefort quarry.