Arezki Group has been into operation since 1962. Starting from transport and supply of building materials to the various European multi-national companies based in Senegal and Gambia, the company has been evolving throughout decades until the recent years when starting major construction projects for roads, airports and large bridges. As for the period from 2015 to 2020, the company counted for almost 600 million USO of scheduled and ongoing work.

Arezki was in contact with Metso Outotec some time ago. The company owns two crushing plants that are currently in operation - one Metso Outotec Nordplant™ in Guinee Bissau, bordering Senegal to the north and Guinea to the south east, and another crushing plant with Metso Outotec crushers in Mansadala, eastern Senegal.

Being pursued an excellent and consolidated relation with our team in the past, the client decided to trust on Metso Outotec solutions this time as well. Our team supplied two new Nordplant™ crushing plants to increase Arezki aggregates production capacity, needed for road and other construction works to be implemented. The team also provided solutions for aggregates, including mechanical and electrical engineering and manufacturing, transport, commissioning, and on-site trainings. Both projects were implemented successfully in 2020 despite the COVID-19 difficulties.

After the full two plants delivery and the road construction, both plants can supply the needs of the region in terms of aggregates for other infrastructure construction - this will bring benefits for the whole West Africa region.

CHALLENGE

- Bad condition of a part of a strategically important road

- Inland site locations and not enough infrastructure to transport materials for a more efficient road construction

- Not enough aggregates and quality for various other construction works in the whole region

- Short delivery time

- COVID-19 challenges

Not enough infrastructure and insufficient supply of aggregates

N1 road is the national road of Senegal. lt connects the west and the east of the country - starts at Dakar Port, the farthest point of the West African coast, and continues up to Kidira, located on the border with Mali. There`s no doubt - this road, connecting two countries, is of strategic importance for the whole West Africa region.

A part of this road, starting from Mansadala, located in Tambacounda region, and finishing on the border with Mali, especially needed rebuild. In order to upgrade this road section, it was a must to urgently create infrastructure in the two sites, located inland at each end of the road - Mansadala and Kidira, and ensure efficient and high quality aggregates production for various construction works, including this road's.

For this, Arezki implemented a global project to upgrade the existing Mansadala site so to increase its capacity, and build a completely new plant in Kidira. This place was chosen because of strategically relevant location at the end of N1 road, next to the border with Mali.

lt must be highlighted that implementation of the projects happened in 2020 - in the times of intensive and difficult COVID-19 situation, bringing its own challenges for the work organization, especially when having a short delivery time. During the pandemia, it was challenging for Metso Outotec supervisors to travel or continuously work on-site respecting safety distances and protocols. Also, the team experienced challenges on logistic operations and shipments.

SOLUTION

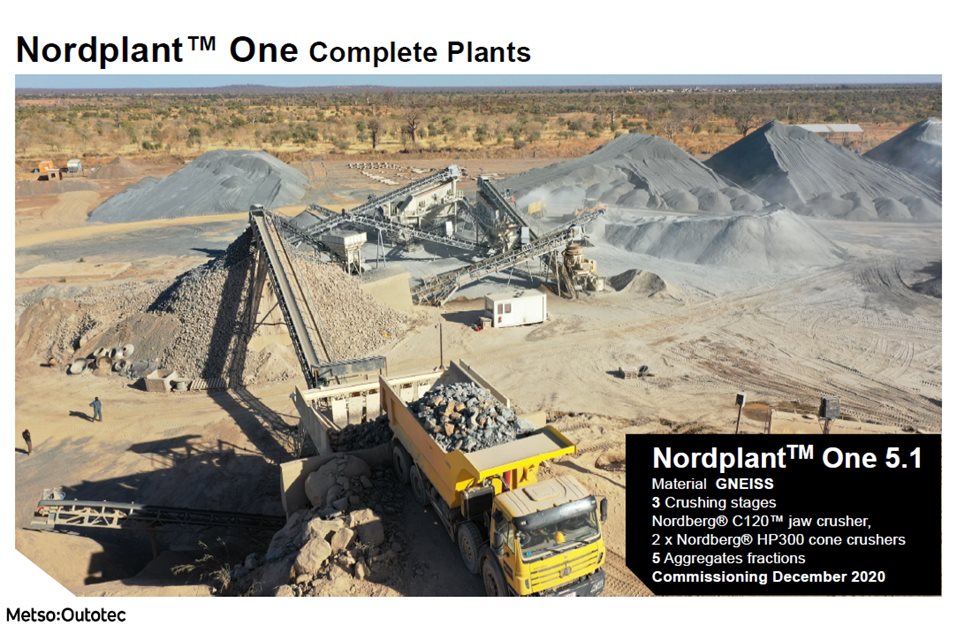

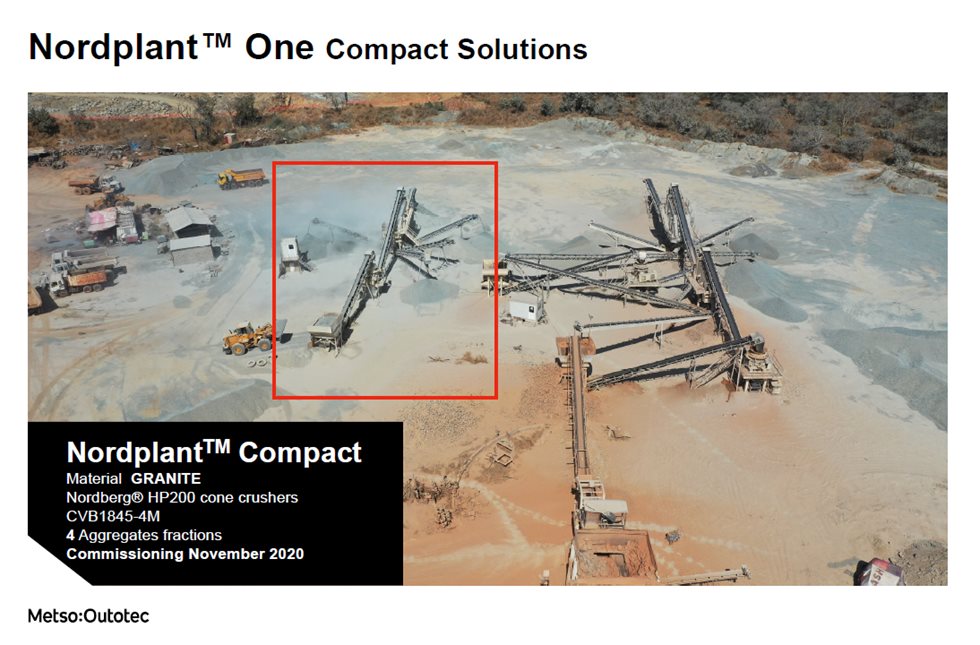

- 2 new aggregates solutions: Nordplant™ 5.1 Complete plant and Nordplant™ Compact HP200 CVB1845-4M

- Pre-designed solutions for high aggregates quality and fast delivery

- Full package including machines, steelworks, conveyors, and electrical equipment

- Service in one-hand: managed engineering, transport, provided supervision for mechanical and electrical assembling, plant commissioning and on-site training for operators

- Plants with new design and advanced technologies

Delivering end-to-end solutions

For this project, in order to increase aggregates production, the client ordered two new Nordplant™ crushing plants with new design and advanced technologies, and installed them in two different locations at the same time - Kidira and Mansadala.

In a new site of Kidira, there`s now a complete crushing and screening plant, Nordplant™ 5.1 with intermediate stockpile, including VF561-2V C120 2xHP300 CVB1845-4M CVB2060-4M. This full solution including machines, steelworks, conveyors and electrical equipment was delivered by Metso Outotec team.