OceanaGold Corporation holds a diverse portfolio of assets in New Zealand, operating three mines on the South Island, including one of the largest gold operations in the country. The company acquired the Didipio Project in the Philippines through a merger with Climax Mining.

Located on the island of Luzon, approximately 270km north-east of the Philippine capital of Manila, the Didipio Mine is a high grade gold-copper development forecast to produce 100k0z gold and 14kt copper on average over its projected 16-year mine life. Didipio Mine was commissioned in 2012, with commercial production commencing April 2013.

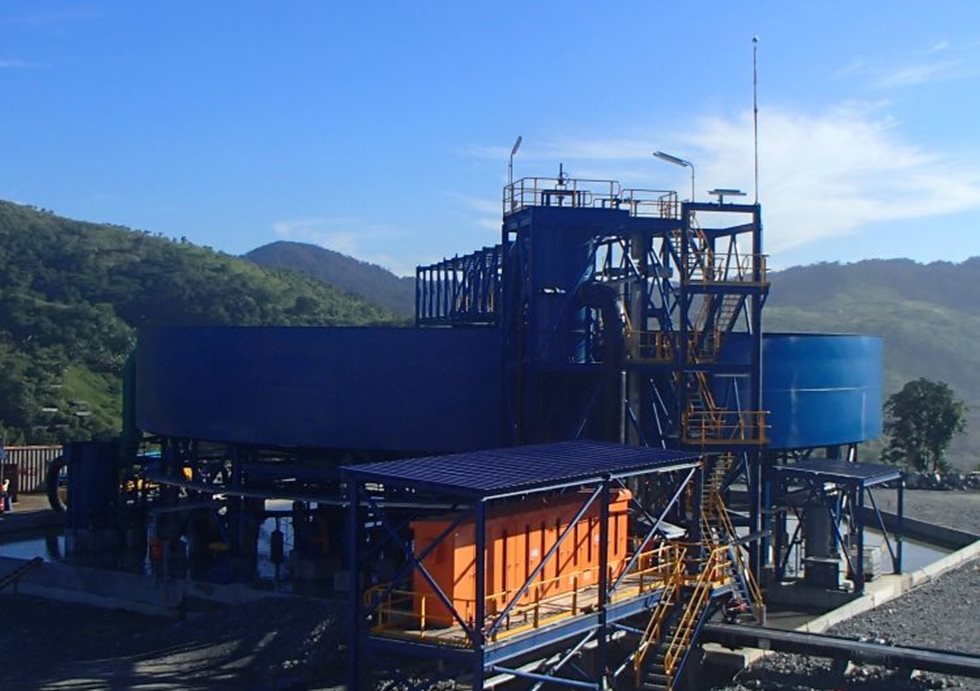

In Q3 2013, OceanaGold identified an opportunity for a new water treatment plant to treat the existing tailings storage facility outflow in order to reduce total suspended solids. The plant would also take into consideration future removal of metals precipitated from solution.

Outotec and OceanaGold have a strong track record of collaboration together, with Outotec supplying all the main processing equipment for the Didipio Mine, including comminution circuit, flotation, filters, thickeners, and automation. Outotec also installed the world-first flotation cell, TankCell 300, at OceanaGold’s Macraes mine in New Zealand, which at the time was the largest flotation cell ever built.

Process design

Outotec was engaged to carry out pre-feasibility engineering studies for the water treatment plant, as well as subsequent pre-study work. An extensive testwork programme was also undertaken on site to design the process using Outotec’s dynamic bench scale high rate thickener. The programme was critical to proving the process performance could meet stringent targets across an extensive design envelope, with the water treatment plant feed fluctuations being seasonally driven.