Aiming for sustainable performance

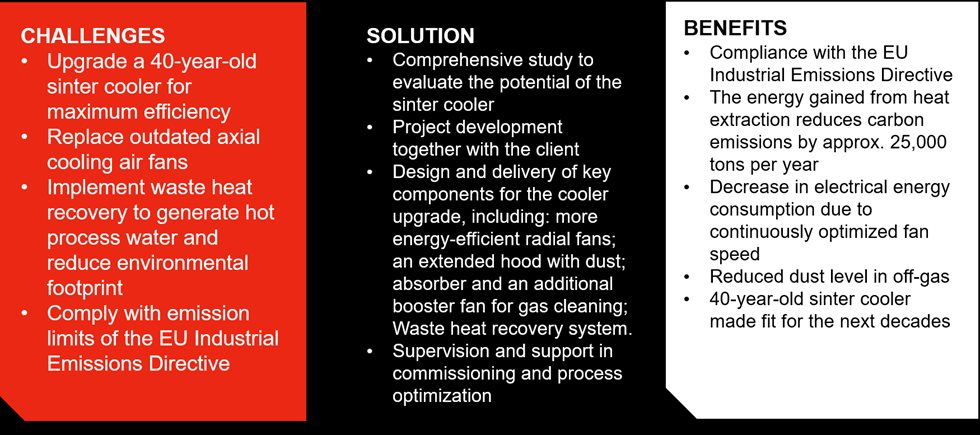

Two of Dillinger Hütte’s sinter plants had been producing a reliable feed for the blast furnaces, but sinter plant 3 had to be optimized consistently. In addition to the need to improve the availability of sinter plant 3, the company wanted to make improvements, for example, in the plant‘s energy consumption and emissions levels.

This is where Metso Outotec stepped in to support the company to find a sustainable solution. The co-operation started with a comprehensive study to design the required equipment to implement the planned improvements. With the final decision of our customer to implement the identified measures, Metso Outotec entered into a partnership with the brownfield specialist Küttner from Germany. Based on the long-term experience of Metso Outotec in sinter technology and process and plant engineering and the vast experience of Küttner in the fields of heat recovery, gas cleaning, and automation an entire integration concept was developed.

The key actions included, for example, retrofitting the cooler at the sinter plant for maximum efficiency. Outdated and inflexible axial cooling air fans, which had low energy efficiency, were also replaced. Another important aspect of the upgrade project was the evaluation of the possibilities for waste heat recovery to generate hot process water in order to reduce the environmental footprint.

It was also important to comply with the new emission limits of the European Industrial Emissions Directive (IED), which commits plants in the European Union (EU) to control and reduce industrial emissions.

Results with thorough studies and accurate design

Metso Outotec supported the customer for more than five years in this complex project – from the very first idea to the final modernization of the old sinter cooler and the implementation of a waste heat recovery system.

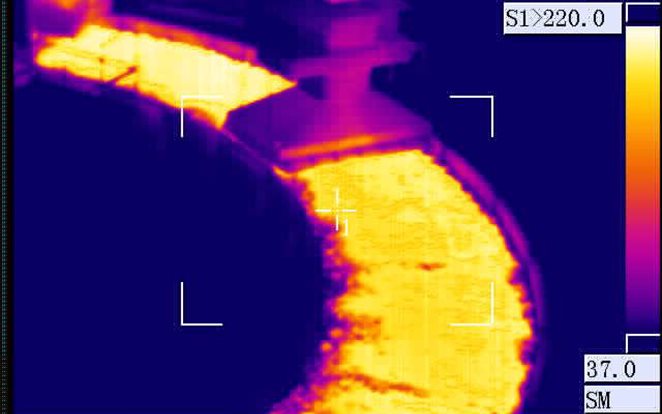

In 2015, Metso Outotec experts carried out a comprehensive study to evaluate the potential for cooler modification and reduction of emissions as well as different possibilities for waste heat recovery. For this, Metso Outotec designed a small mobile hood to measure gas volume, temperature, and dust load in the different sectors of the sinter cooler. By means of infrared cameras, heat distribution in the sinter bed in the cooler was investigated.

Based on the results, Metso Outotec studied different scenarios to utilize the waste heat of the sinter cooler in the generation of electrical energy or hot water and in other areas. Dillinger Hütte decided that hot feedwater generation for the power plant would be the most economical approach. Heat recovery now generates an additional 82,000 MWh of energy, and this equals a reduction in carbon emissions of approximately 25,000 tons per year.

In close cooperation with Küttner the cooler modernization was implemented in 2020. The upgrade included an extended hood with a dust absorber and an additional booster fan for gas cleaning as well as new cooling air fans and a waste heat boiler. The modern radial fans with variable speed drive control are more energy efficient. By always operating the cooling air fans at the minimum required speed, it is expected to save up to 20% of the energy consumption in the long run. The new dust absorber system allows the dust level in off-gas to be continuously kept below 5 mg/Nm³.