Headquartered in Melbourne, Australia, MMG Limited is a mid-tier global resources company that mines, explores and develops base metal projects around the world. They operate and develop copper, zinc and other base metals projects across Australia, the Democratic Republic of the Congo, Laos and Peru. They also have significant exploration projects and partnerships across Australia, Africa and the Americas.

Operations

MMG’s Rosebery is an underground polymetallic base metal mine located in Tasmania, Australia. It has operated continuously since 1936. Zinc, lead, copper concentrates and gold ore is produced at Rosebery, using mechanized underground mining methods, then crushing, grinding and flotation processes. Rosebery produced 74,803 tonnes of zinc in zinc concentrate and 26,611 tonnes of lead in 2017.

Background

When an operational filter reaches 30 years old at any site, it’s quite a significant milestone. Built in 1987, beset with premature wear, aging parts, and recurrent corrective maintenance, the standard response might be to replace the old filter with a new unit. At MMG Rosebery, however, they went for a different approach.

In April 2017, MMG Rosebery engaged Outotec to review its filter equipment and filter maintenance program. This initial audit included assessing the physical condition of filters 1, 2, 5 and 6, as well as a review of regular and preventative filter maintenance practices.

The four pressure filters at Rosebery were all aging, requiring regular unscheduled maintenance. The filter in most urgent need of attention was Filter #6. Outotec reviewed various options, including the purchase of a new hydraulic filter. Apart from capital cost, a hydraulic filter would necessitate new flooring in the filter room, an expensive undertaking. Although refurbishing the old filter would be complex, this challenging project could be delivered with meticulous planning and a partnership approach between Outotec and MMG.

Scope

Following this audit, Outotec was tasked in May 2017 with the design to refurbish filter #6. The scope comprised design, supply of all new and refurbished components, with Outotec providing supervision services during on-site refurbishment and filter commissioning. Outotec was also to deliver filter training services to Rosebery maintenance and operations personnel, along with full documentation support.

Partnership and communication

It was a complex project to manage, so a partnership approach and regular communication between Rosebery and Outotec was critical. Explains Matt Orton, Maintenance Superintendent at Rosebery “Outotec’s project planning and preparation was excellent. We were regularly appraised regarding the progress of the build and dispatch from Europe”.

Internally within Outotec, we conducted weekly meetings between various project teams in Australia and Finland, covering manufacture, delivery and installation. All possible bottlenecks, risks or delays were proactively eliminated. Progress updates via QA reporting milestones were then regularly communicated to MMG Rosebery.

Expertise and planning

Although the filter was 30+ years old, Outotec’s database was such that it could locate original site drawings, saving valuable time. This also quickly ensured an accurate, comprehensive list of mechanical filter components. With an established reputation and extensive experience in filter upgrades and refurbishments, Outotec was familiar with the challenges and pitfalls of such a complex job.

Explains Matt Orton “Outotec sent one of its filter technicians for a pre-shut audit to ensure an efficient installation. We avoided any last-minute delays with this initiative”. As Rosebery was using a mixture of new components, on-site refurbishments and site spares stock, this audit proved invaluable.

Two additional site days were spent by the filter technician on pre-planning and methodology for stripping and refurbishing the components. The experienced technician also ensured all components, refurbished and original, were organized in a manner to ensure an efficient and seamless install.

Filter refurbishment

As part of the scope, Outotec provided advisory services to oversee the filter rebuild. Two Outotec filter experts arrived 13 March 2018 just prior to site outage. They met with the Rosebery team to identify safety hazards and finetune the filter refurbishment plan. Once the filter was stripped down and all unusable parts removed, the refurbishment of the filter began.

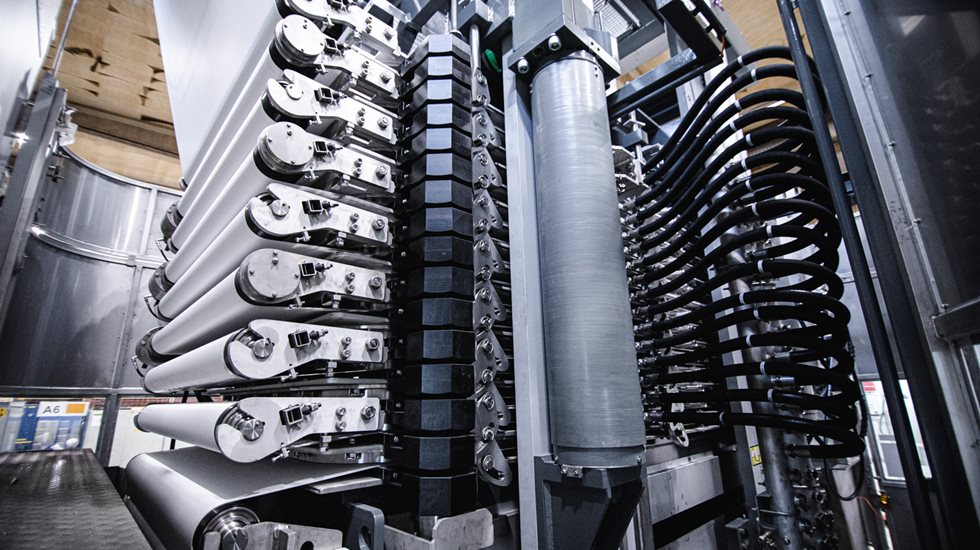

New components included the filter upgrade was the plate pack, top and bottom pressing plates, foundation plate, filter base frame, pinch/butterfly valves, process feed/filtrate and pressing water hoses, cloth wash spray bars, cloth wash filter strainer, cloth tensioning unit and cloth drive unit.

The existing front vat tray was cleaned and reused, with vat rollers replaced. Some existing components were refurbished, including filter columns, closing device scissor and plant process pipelines. The original cloth tension/cloth drive motors were in good working order, so were included in the rebuild. Serviced spares from Rosebery’s stores, such as the motor for the closing device, were also used.

Outotec filter experts and MMG’s installation team split into day and night shifts for the refurbishment. Round the-clock commitment delivered a refurbished filter two days ahead of schedule, on 23 March 2018. Importantly, the refurbishment also occurred with zero injuries onsite.