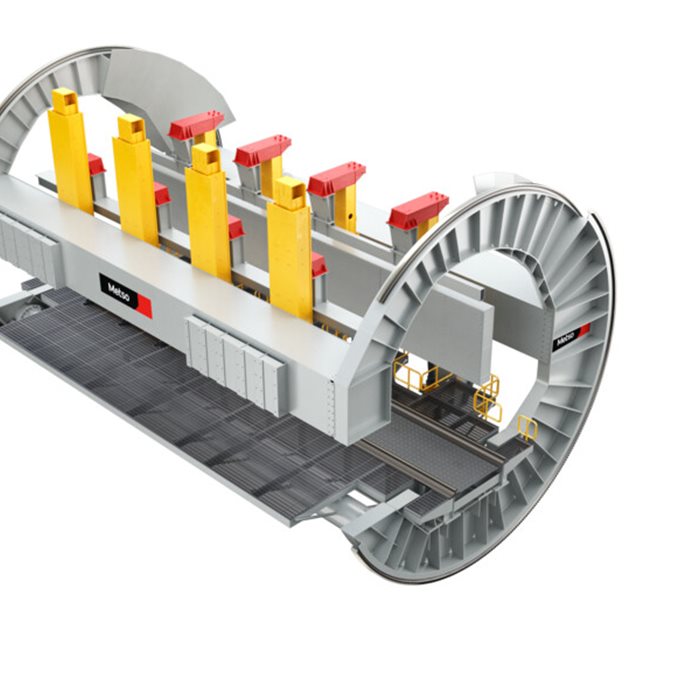

Metso Railcar Unloading Solutions has over 115 years of industry experience and consistently is setting new industry benchmarks. With a large global installation base, we offer a wide range of coverage in both applications and industry segments.

Our second to none process expertise with class leading design and engineering capabilities meets any project need no matter how challenging or complex. With our complete portfolio of equipment, find an integrated and dependable solution that helps drive productivity goals.

Industry setting benchmarks:

- Unloading up to 100 cars per hour or more

- Unloading rates up to 11,000 tons per hour or more

- Up to 178 tonne pull

- Hauling speed up to .76 meters per second

- Move up to 240 cars per hour

Key benefits:

- Lowest total cost of ownership

- Completely automatic operation

- High availability

- Low maintenance requirements

- High throughput