Designed by the world’s leading pelletizing plant supplier to meet the future demands for your pelletizing plant

An effective way to minimize CO₂ and NOx emissions from the combustion process.

- Hydrogen as carbon free fuel to support decarbonization

- Substantial reduction of NOx emissions by up to 80% with natural gas

- Low thermal penalty on natural gas ~ 10%

- Increased product pellet homogeneity and quality

- Increased refractory lifetime

- Optimization of NOx vs. Opex balance with digital solutions

- Proven technology

- Easy retrofit of existing plants

Attain CO₂ and NOx emission targets in a cost-effective manner

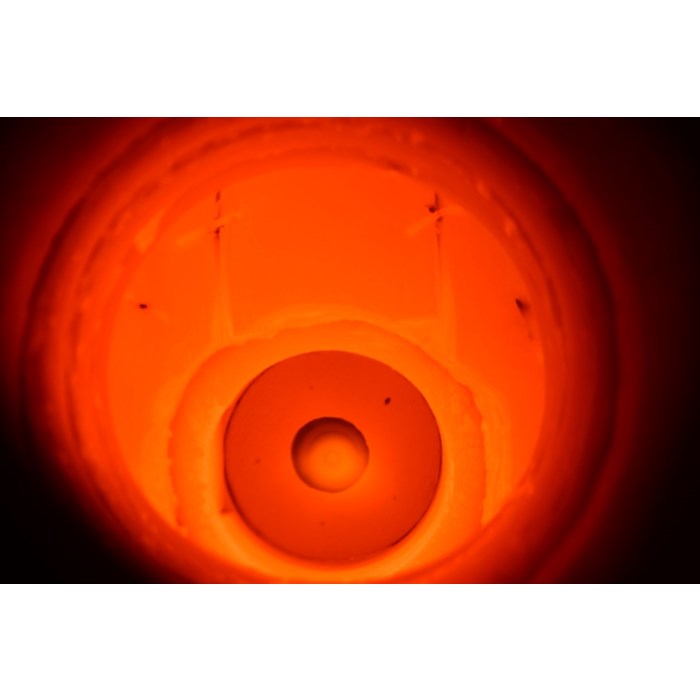

Own proprietary Ferroflame™ burner family for travelling grate pellet plants:

- Standard burners

- Hydrogen burners

- LowNOx burners

- Convertible gas burners, prepared for later easy conversion to LowNOx operation

Services

- Combustion audit and process evaluation

- Modelling (CFD and physical)

- BMS and flame safety

- Burner ancillaries (ignitors, pilots, support systems, fans)

- Gas and oil valve trains

- Fuel system design

- SNCR systems

- Site survey, process audit, detail design, training, spare parts and many such services available on request