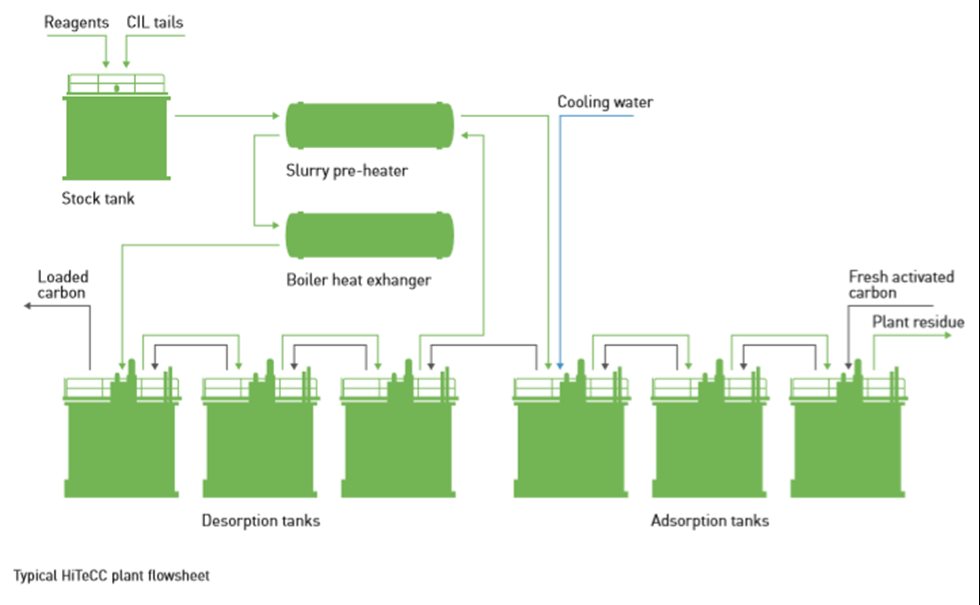

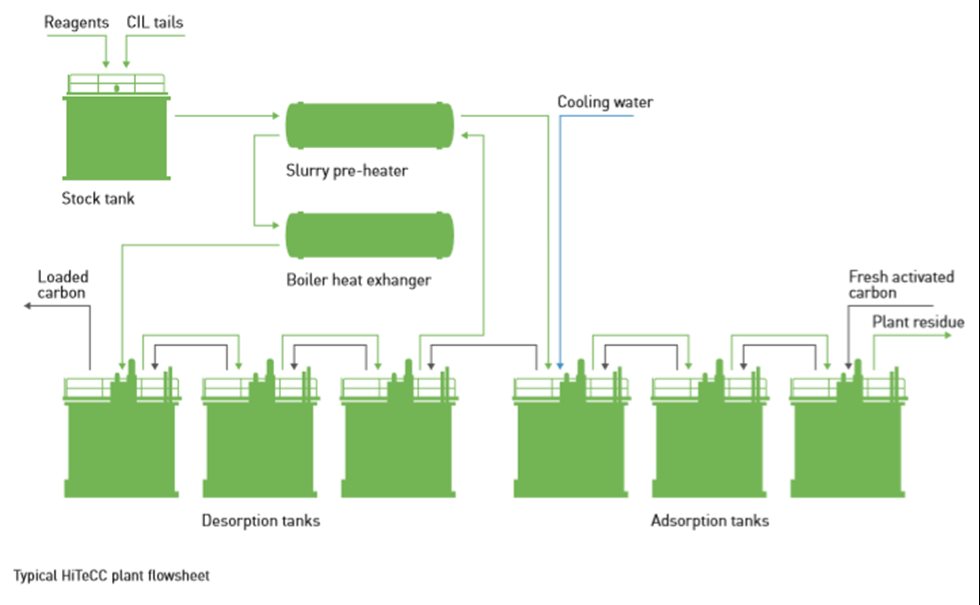

Desorption stage

The feed to the HiTeCC plant is heated through a series of heat exchangers to between 50 and 80°C depending on the ore characteristics. Caustic is added to change the ionic strength of the solution and, in combination with the heat, aids in desorbing the preg-robbed gold from the natural organic carbon. Adsorption of the dissolved gold onto activated carbon already starts in the desorption stage.

Adsorption stage

Following the desorption stage, the slurry is cooled down to ambient temperature to aid in the adsorption of the remaining soluble gold onto fresh activated carbon. Carbon levels in the tanks are controlled to optimize gold recovery.

The energy balance and efficient recovery of heat between the desorption and adsorption stages is important for the HiTeCC process to reduce both the overall energy requirement and the operating cost.

Suitable for a wide range of preg-robbing feed material

Each HiTeCC solution is customized according to the project in question. The process can be configured to treat a wide range of feed material, including:

- Oxidized sulfide concentrates, including BIOX and Pox residues

- Non-refractory sulfide concentrates

- Carbon float concentrate

Ongoing R&D and process improvement

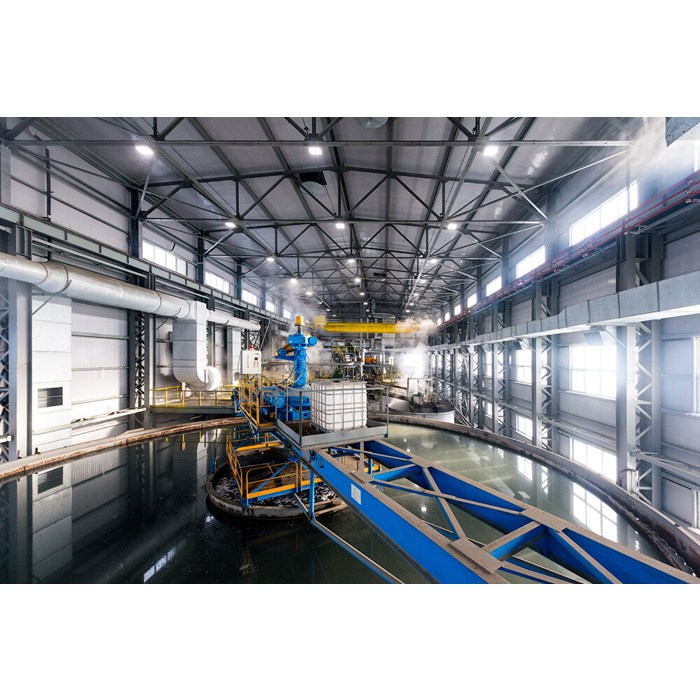

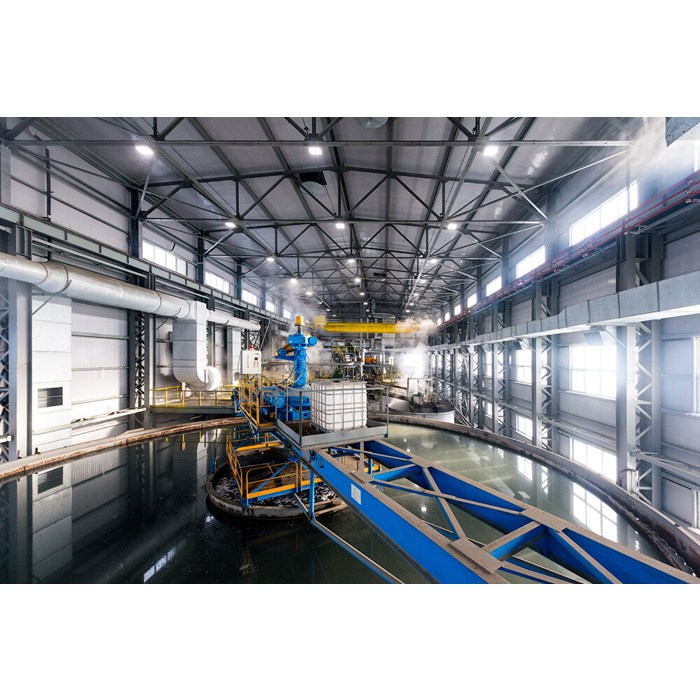

A hot caustic leaching process was developed and implemented at Kirkland Lake’s Fosterville BIOX operation in Bendigo, Australia. Extensive batch and continuous pilot plant test work was undertaken by the mine metallurgical team during process development, leading to the commissioning of the hot caustic leach circuit in 2009.

In 2012, Outotec (then BIOMIN), in agreement with Kirkland Lake Fosterville, developed the technology further, leading to the birth of the HiTeCC process. Metso has been expanding its HiTeCC technology database through focused research and development programs. The company has also been utilizing industry experts to advance its understanding of process fundamentals, process modeling, and process design development.

Moreover, Metso has been delivering process design solutions for clients who are currently confronted with sub-optimal gold recoveries owing to the presence and varying severity of preg-robbing material.

Enabling more efficient use of natural resources

The HiTeCC process is a truly sustainable technology as it unlocks value in current projects and historical tailings that would otherwise not be technically or economically feasible to recover.

The process design incorporates energy-efficient heat exchangers, and the byproducts of the process are benign and can be safely deposited into a tailings storage facility.

Robust technology

The operation of both the Fosterville and Suzdal HiTeCC plants have confirmed the robustness and simplicity of the HiTeCC process. The process is not sensitive to treating a combination of current CIL residue and reclaimed historical CIL tailings, while maintaining process performance.