Flexibility

Fully mobile, modular and configurable designs and can be used as stand alone or multi-stage crushing

Ease of maintenance

Ease of access to service points, simple and quick component replacement without hot works

Safe and simple operation

Fully integrated, smart automation features and remote control ability

High productivity

High throughput, high reduction rate, high capacity and handles wide range of materials

Fully integrated, productive and flexible crushing solution

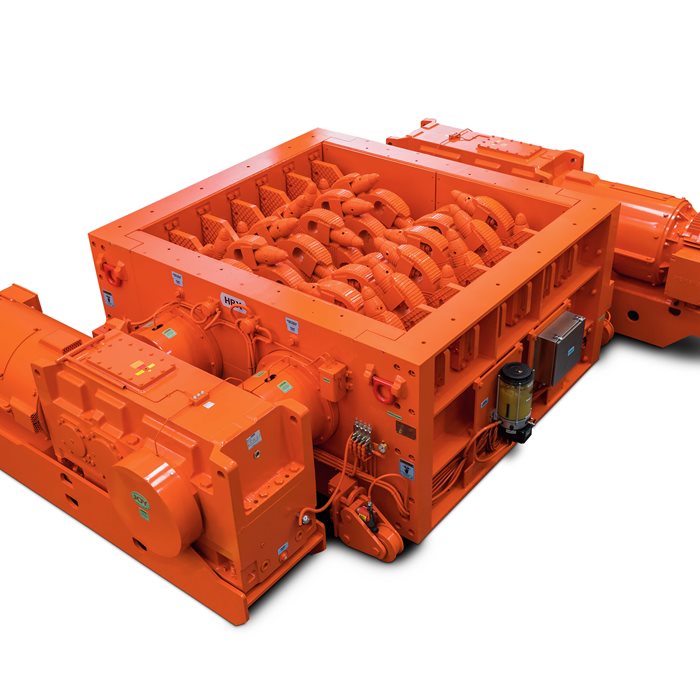

Metso's collaboration with Komatsu brings a new, sizer crusher into our portfolio. This opens new opportunities once paired with our proven Lokotrack® units in the soft ore and aggregates applications.

The Komatsu sizer crusher reduces fines generation through matched velocity technology (MVT), while optimizing throughput capacity. Roll speeds are set to match the speed of incoming material, reducing excess fines created with other designs.

Learn more about Komatsu sizer crushers here.

When combining the Lokotrack® mobile sizer with Lokolink™ conveying systems, you recieve a boost in overall efficiency. This also allows Metso to provide a truckless solution right from the pit or quarry to the concentrating or cement plant.

This helps reduce CAPEX and OPEX, while boosting uptime and operational efficiency of your plant.

Learn more about Metso Lokolink™ conveying systems here.

Common soft ores include coal, iron ore, bauxite, dolomite, quartz, industrial minerals and more. Metso has a complete portfolio of equipment to help optimizer your operations and maximize productivity in soft ore applications.

Lokotrack® mobile sizer technical specifications

{{decodeHtmlEntities(field.label)}} |

|---|