Benefits

Less downtime

Better operating results

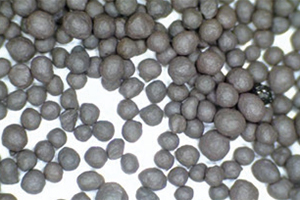

Metso Xresist™ is a high density, alumina ceramic bead-filled toughened epoxy system designed for protecting equipment from wear and abrasion caused by handling and processing particulate matter in solid or slurry form. It is ideal for use in transfer chutes, feed boxes, and sumps.

Difference in composition

Laboratory tests revealed significant improvement

{{decodeHtmlEntities(field.label)}} |

|---|

Spin test

Less volume lost = better protection

Grit blast test:

Less volume lost = better protection

Lap shear test:

Higher load = better adhesion

Side impact test:Impact resistance

More energy needed to break = better impact resistance

T-peel test:

Higher load = better adhesion