Aimed to optimize your availability and production with our extensive expertise

A world-class team of service experts globally

Global expertise and local presence in over 50 countries around the world.

Applying the strictest standards and tolerances for guaranteed safety and reliability

From original to third party to installation, we can support any equipment type

- Prevent issues with automatic sensing and continuous condition monitoring

- Decrease downtime by up to 60% with our innovative digital inspection solutions

- Increase performance with correctly aligned components operating together within tight tolerances

- Maximize gear life and performance with the correct lubrication system

- Minimize wear by keeping contaminants out of your lube system and gear set

- Smooth ramp-up with OEM installations completed to exact specifications by those who know the equipment best

A recurring need for our customers is to continually meet demanding production requirements. To

achieve these targets, uptime and reliability must be improved.

Whether you want to restore or upgrade your mill, we have you covered. Replace worn or damaged parts to run as new or have our engineers redesign them for nextlevel performance. We also offer inspections, diagnostics, monitoring and component upgrades.

Our field experience and equipment knowledge allows us to understand the fundamental requirements of your operation. We can determine the most suitable changes to implement in order to reach your production and sustainability goals.

Inspection packages and digital evaluations

Detect the undetected. Discover potential issues before they turn into real problems. We offer three progressive mill inspection packages to check the health of your horizontal grinding mills, detect problems early and meet your production and sustainability targets. Our advanced digital gear inspection method enables efficient gear inspections with outstanding accuracy compared to the use of conventional methods with up to 60% less downtime due to quicker inspections.

Alignment services

Uneven temperatures and excessive vibration are often signs of misalignment. If not treated, premature wear and cracking can occur. We provide complete alignment services using modern tooling and best practices gained from thousands of field installations. Our experienced professionals with many drivetrain arrangements ensure alignment is always performed to OEM specifications.

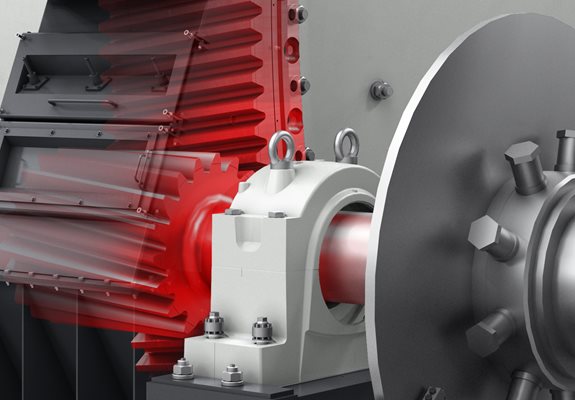

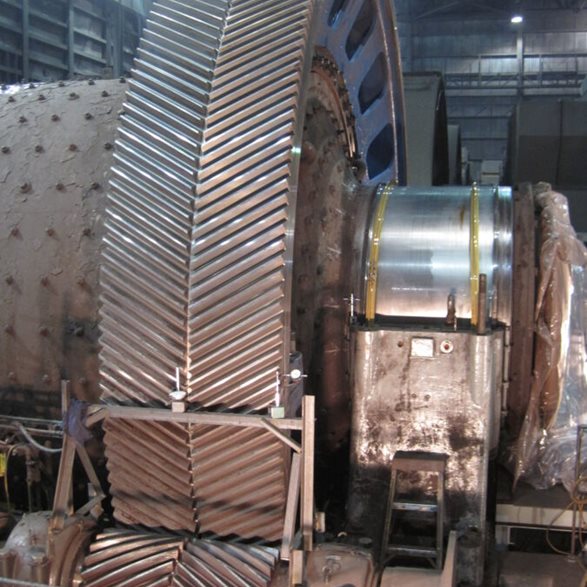

Gear set replacement

When selecting a replacement gear set, optimizing the design can result in cost savings, greater quality and quicker delivery. As the OEM, we have detailed drawings, design expertise, as well as an in-depth understanding of gear, pinions and the components they interact with. We collaborate with multiple manufacturing facilities worldwide to optimize quality, cost and delivery.

Temperature monitoring

Proper pinion temperature control can mean the difference between a healthy asset life cycle and damaging loss. We have enhanced our automated infrared condition monitoring protocol by adding a thermographic camera to analyze the gear set profile temperature and help prevent component damage.

Design upgrades

When greater production is required, there are many factors to consider. We can help improve the performance of gears and pinions by redesigning them for greater strength and resistance. Evaluations are also done to ensure other mill components can handle the new loads.

Lubrication systems

Proper lubrication is vital to the life and performance of your gears. Our gear spray systems are engineered to automate lubrication quantities and spray frequencies according to your specific gear set and lubricant. Gear guards are upgraded with new seal configurations to minimize contamination and system failure.

Installation and reversal

If components are not installed properly, misalignment and excessive vibration occur, which can shorten the life of your gear and pinion. Our qualified field service and engineering experts ensure proper installation to OEM specifications. They are also capable of reversing the gear to extend its useful life.

Gear flushing and cleaning

The cleaning of production equipment is a fundamental aspect of maintenance to control the risk of contamination, to ensure quality and plant safety. Gear cleaning and flushing are imperative for visual inspections to ascertain the condition of the equipment.

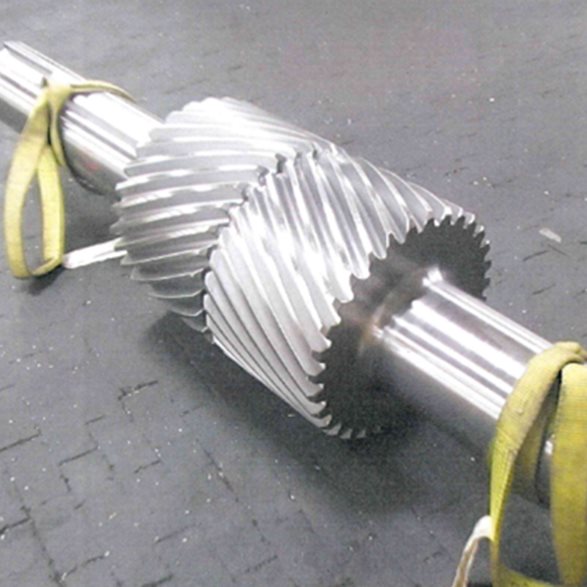

Pinion solutions

Pinions are a highly customized and critical component of grinding mill operations. When a pinion is damaged during operation, production stoppage results in costly operating expenses and lost production time. Our drop-in pinion solution allows you to specify a pinion assembly that best suits your maintenance strategy and risk management practices.