Q1. What sparked the development of the HP cone?

MK: The origin of the HP series cone crusher can be tracked backed to Milwaukee, USA in the early to mid-1980s. Nordberg USA, a Metso predecessor, wanted to gain a better understanding of their customers’ priorities in the crushing process. Research showed that mineral processing was highly influenced by capitalizing on machine parameters such as head throw, head angle, crusher setting and head gyrations per minute. The technological breakthroughs re-defined crushing performance and provided the basis for the newly designed cone crusher introduced in 1989: the Nordberg® High-Performance cone crusher series, today simply known as the HP.

Q2. What made HP the new norm in performance?

MK: The HP became an industry standard as a highly portable crusher for aggregates applications and smaller mining applications. HP is capable of increasing plant production while fitting into the existing crusher foundations. For example, an HP400 cone crusher with a power rating of 400 horse power fits the foundation designed for a 4-1/4 foot Symons cone but with the capacity of a 5-1/2 model.

Q3. What was the key benefit to the customer?

MR: The revolutionary advantage of the Nordberg HP Series was that whilst keeping a similar setting, the customer was able to achieve a yield superior to the existing Symons cone, the reference at the time. The aggregate market was evolving quickly in the 1990s, demanding tighter quality standards for aggregate production. HP proved to be ahead of the game in creating new standards for shape and end-product quality.

Q4. Can you share some light on the first HP installations?

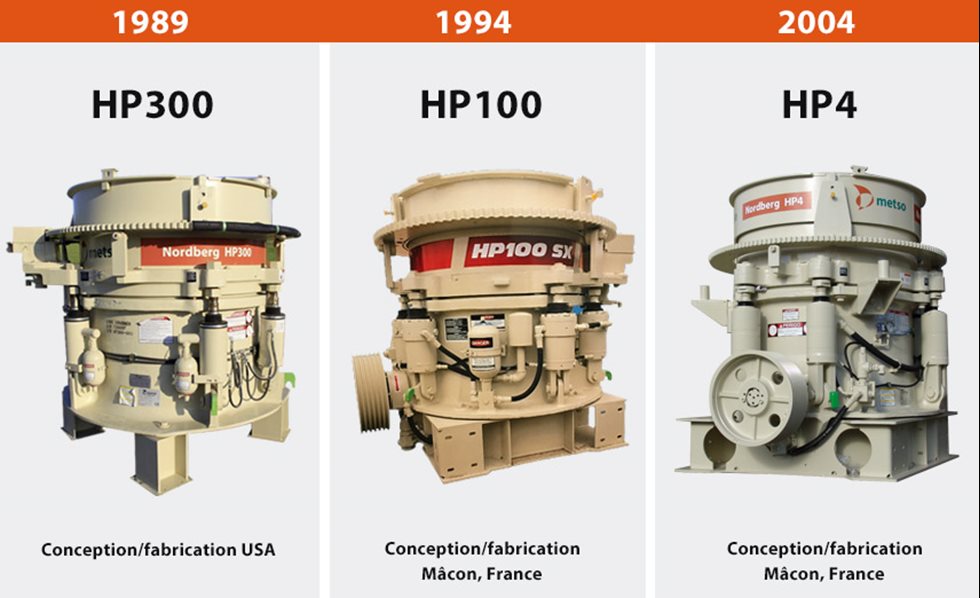

MK: The first HP Series cone built was the HP300. This crusher was installed as a prototype crusher at a customer quarry in Georgia, USA. It was delivered in July of 1989 and used as a secondary crusher. Since then, I have commissioned countless HP Series cone crushers. It never gets old when we start up a new crusher and see the look on the customers face as they realize the performance of the HP, both in tons per hour and product shape.

Q5. What was the next step in the evolution of the HP?

MR: The HP design and manufacturing soon expanded to Metso’s production facility and engineering office in Mâcon, France. In 1995, the first HP100 model, smaller yet strong in performance, was launched on the market. Today, HP design is still located in Mâcon, while manufacturing takes place in Metso competence centers around the world, in Brazil, China, India and France. Versatility is the key with these crushers providing a wide range of fixed and mobile applications. The Lokotrack® LT200HP™ and Lokotrack LT200HPS mobile cone crushing plants are popular machines today for their compact size and proven efficiency.

MK: The next generation of HP Series cone crushers, the HPX were introduced in 2004. Building on the high-performance features of the original HP Series but with enhancements such as a head brake, an improved tramp release cylinder and accumulator design, all designed to respond to customers’ continuously evolving needs.