Lokotrack® LT200HP™ mobile cone crusher is typically used as a secondary crusher in conjunction with a primary crushing plant in multi-stage crushing applications like railroad ballast, asphalt, and concrete fraction production. It is easy to move between sites thanks to compact transportation dimensions.

Efficient high-capacity crushing

Lokotrack® LT200HP™ features an efficient Nordberg® HP200™ cone crusher unit, which is designed for high productivity, low operating and wear costs and a long service life, providing superior end-product quality.

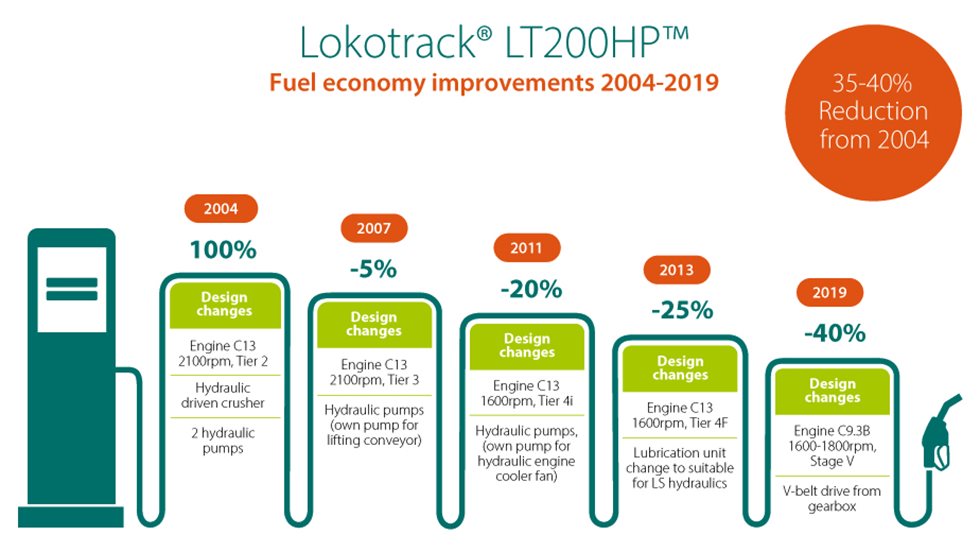

Cost savings in fuel consumption

The fuel economy of the Lokotrack® LT200HP™ has improved by between 35 and 40% since the first model was introduced in 2004. The latest model can save at least 15% in fuel consumption compared to the previous hydraulic-driven model, thanks to its direct belt drive from the gearbox. It is also the first Lokotrack to comply with Stage V emission regulations.

Optimum crushing results

The Metso IC™ process control system optimizes crushing results. It allows one-button start and stop, with built-in troubleshooting and a variety of parameter selections. All Lokotrack® mobile crushers in the same crushing process can be connected to the Metso IC™ system. In addition, the entire process can be conveniently monitored and controlled from the excavator's cab using the Metso Remote IC application for remote process control.

Additional features for Lokotrack LT200HP™

Lokotrack LT200HP™ mobile crusher is available with an extended main conveyor to allow more feeding height for downstream crushing and screening processes. It can also be delivered with dust encapsulation, a discharge hood, a high-pressure water spray system, or a special scraper to clean the conveyor belt. Optional remote control allows the machine to be moved safely from a distance.

Safe and easy maintenance

Metso is investing heavily in its equipment safety and easy maintenance. In Lokotrack LT200HP™, safe and easy daily operations are ensured with an extensive platform and easy access to cone crusher maintenance points.

Ideal for

- Secondary crushing in multi-stage crushing applications

- Road construction

- Railroad ballast

- Asphalt and concrete fractions

Benefits

- At least 15% less fuel consumption: 35-40% compared to 2004 model

- Compact transportation dimensions

- High productivity

- Long-term investment with high resale value