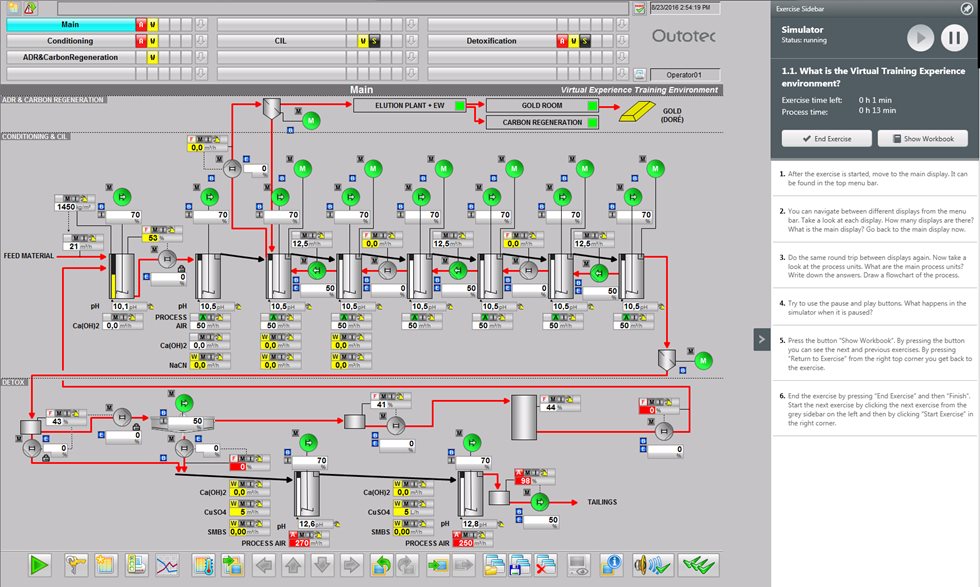

Metso Outotec has had a long history with digital development, with innovative products such as analyzers and control systems dating back to the 1960’s. Since then, further development has been completed. Today, Metso Outotec’s digital portfolio is vastly wide and includes a whole end-to-end offering. There is now the capability to provide any applications based mainly on our own platform development.

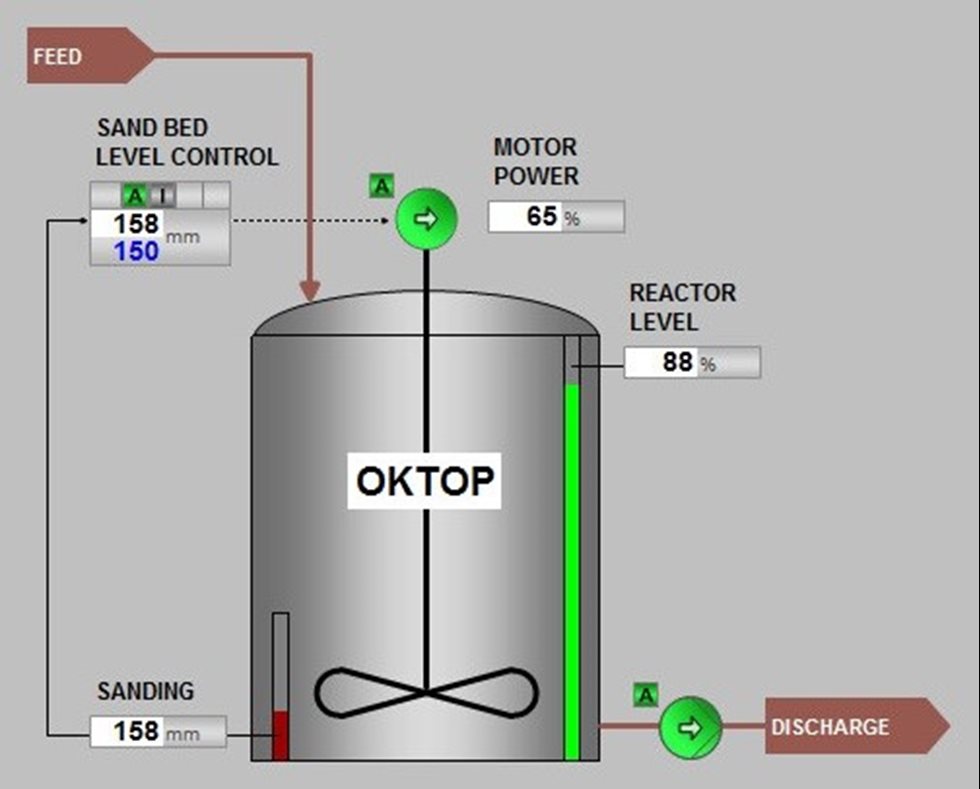

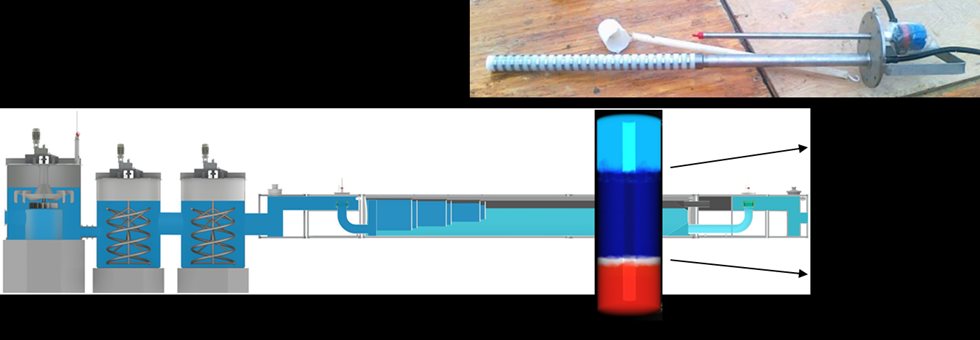

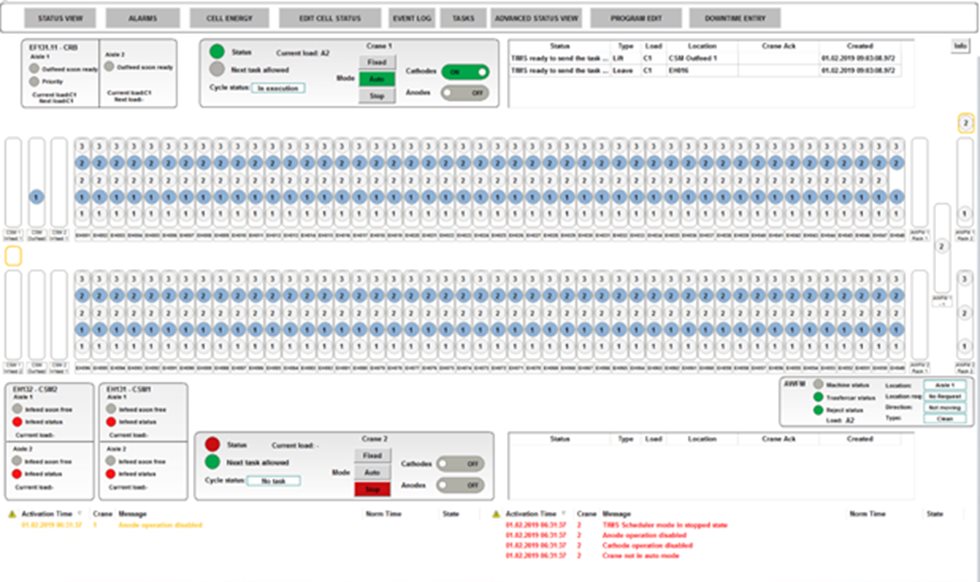

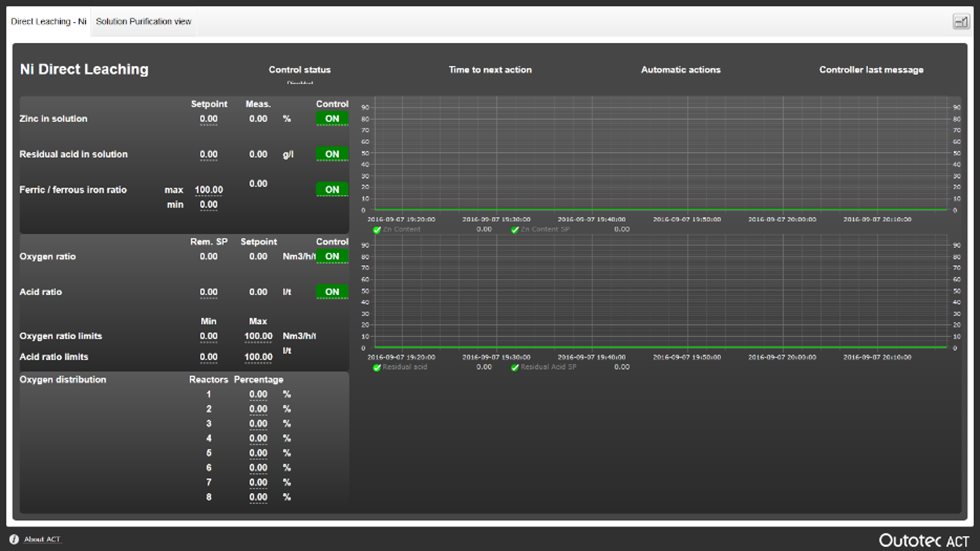

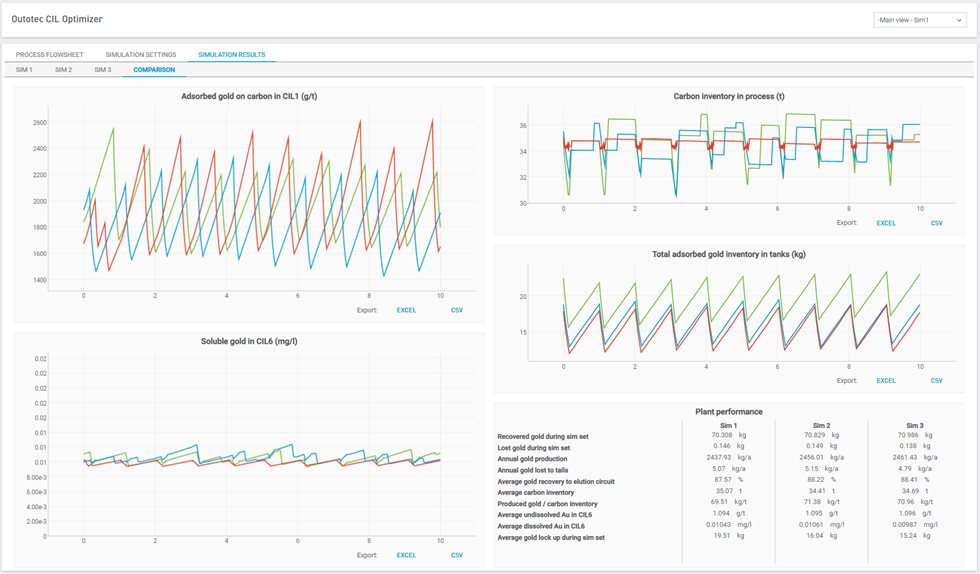

Metso Outotec’s core strength is in combining process know-how, proprietary equipment and plant unit products with digital connected features and local & global services. Our digital offerings for hydrometallurgical solutions cover hardware and software products. With the continuous push to increase production whilst remaining environmentally cautious, Metso Outotec’s hydrometallurgical digitalization allows operations to increase profitability, sustainability and safety – three of the most important factors in the industry today.

CHALLENGES

- Declining ores

- Environmental regulations

- Complex processes

- Maintain safety

- Operation cost

- Visibility of hidden phenomena

- Resource efficiency