What makes a hybrid feeder different than a traditional apron or belt feeder?

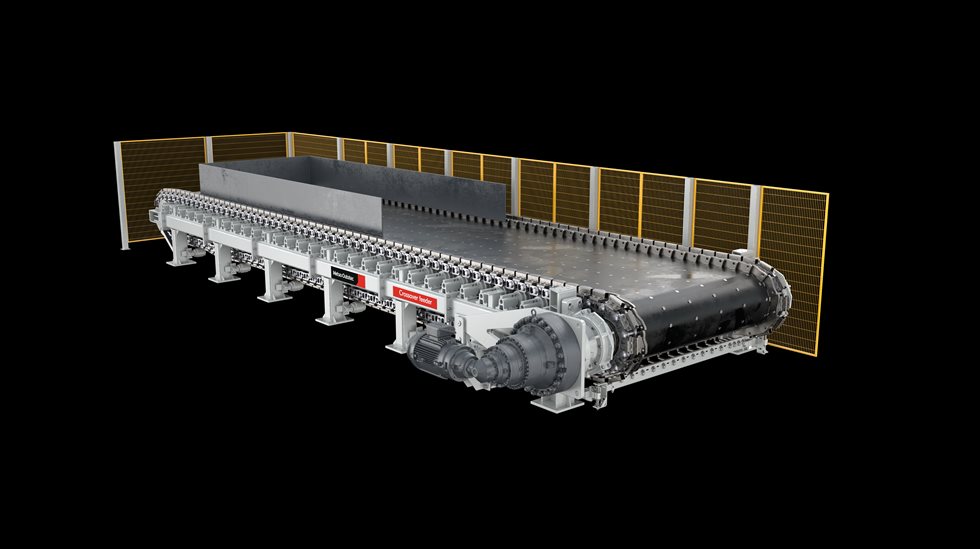

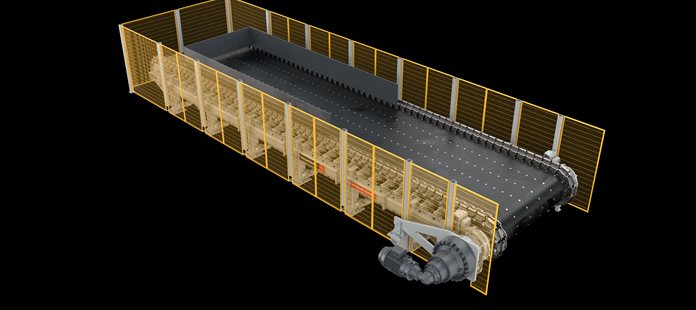

Metso Outotec's Crossover™ feeder is a hybrid feeder that includes features of the reputable ”tractor chain” apron feeder and a reliable belt feeder. The Crossover™ feeder is a unique design of a belt-over-apron concept with an outboard chain and modular construction frame resulting a lower installation height.

What types of applications are hybrid feeders best suited for?

The Crossover™ feeder is suitable for both light and heavy-duty applications. Some examples include:

- Layouts that require handling material of minus 300mm and a sealed conveyor design to eliminate the need of a dribble belt to collect the fines under feeder, are popular installations

- Configurations that require a horizontal transitioning to incline installation

- Applications of feeding secondary type crushers, HPGR’s, mills, screens are also a good choice for the Crossover™ feeder.

These can be either greenfield or brownfield operations.

Installations of direct dumping from haul trucks, rail car dumpers, handling of sharp metal or hot material, should be avoided. This is where traditional apron feeders fit the best.

Will I need a dribble fines collecting belt conveyor under my Crossover™ feeder?

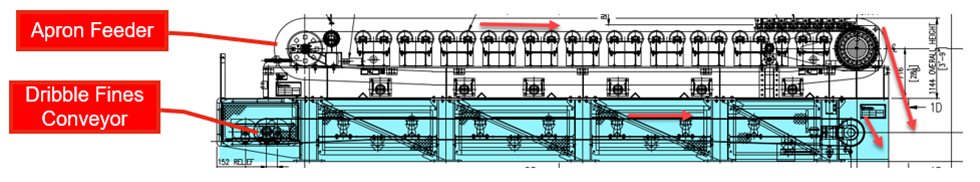

No, a dribble fines conveyor is not required when using a Crossover™ feeder. Since the Crossover™ already incorporates a belt-over-apron concept, that prevents finer material from leaking between the pans and carryback of fine material to the dribble belt conveyor.

Eliminating the dribble conveyor also reduces the overall height by up to 50% compared to a traditional apron feeder and dribble belt configuration.