Innovative, robust and modular design for quicker execution

Reduced height by up to 50%

Lower overall costs for both CAPEX and OPEX

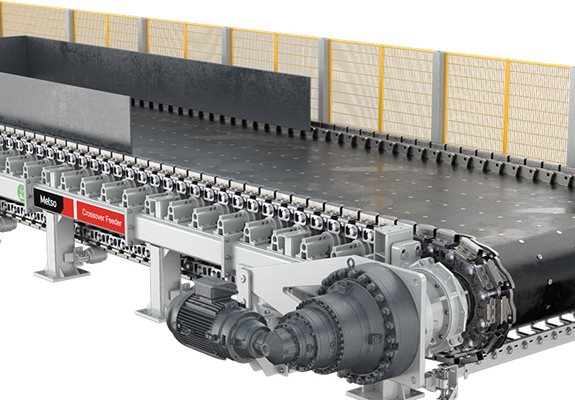

Crossover™ feeder - Experience driven hybrid feeding technology

The Crossover™ feeder design features a reduced height (up to 50%) as compared to conventional feeding technology. This lower height requirement provides an opportunity for CAPEX savings by decreasing the excavation and civil works required.

For retrofit applications, the reduced height profile allows the Crossover™ feeder to readily and economically replace existing feeders including apron and/or belt feeders by lowering modification costs.

Metso's Feeding solutions provide coverage for a wide range of applications and duties in mining. The Crossover™ feeder provides a perfect solution combining the benefits of an apron and belt feeder.

The Crossover™ feeder's optimal applications are:

- As a secondary crushing feeder under a crushed ore bin or slio discharge

- Tertiary stockpile reclaim

- Feeding to a secondary cone crusher

These are some of the optimal application ranges for the Crossover™ feeder, but aways make sure to consult a Metso representative to ensure proper sizing and selection.