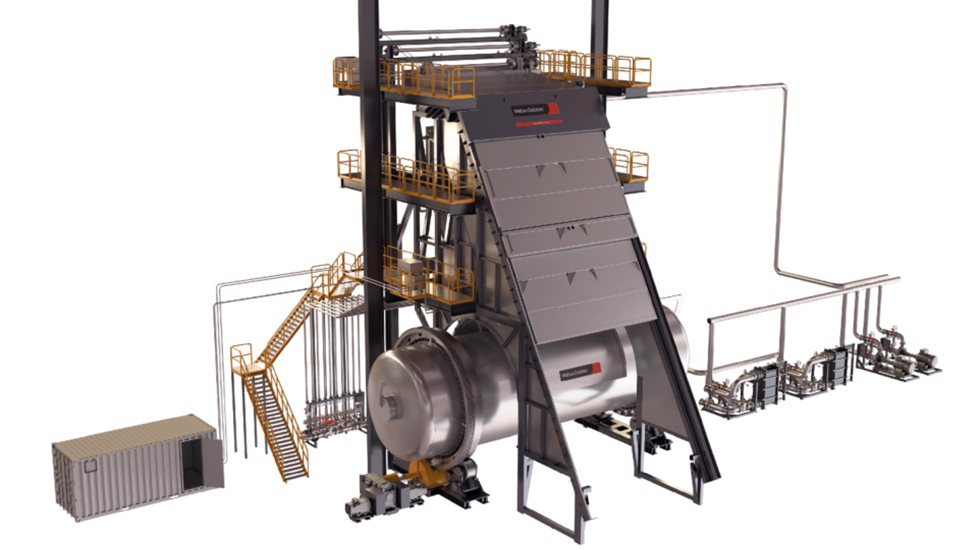

In May 2022, Metso Outotec launched the new generation Converter hood system. The product launch was the first step in marketing of the new Converter hood system. After the product launch, the market has shown a big interest in our new system.

Here at Metso Outotec, we understand our customer’s world and the daily challenges they face. To resolve these issues, our new system addresses the three main challenges that customers are facing today, which include:

- Environmental performance

- Installation and maintenance

- Lifecycle cost

A reliable and properly designed Converter Hood System is essential for maximum efficiency of capturing process gas and avoiding gas emissions during converter operations. The new Metso Outotec Converter hood system fulfils these requirements.

Our system optimizes the gas temperature for equipment downstream in the gas system, gives suitable off-gas composition to the sulphuric acid plant and ensures that no excess gas volume needs to be handled by the gas cleaning system. This gives a maximized gas capturing efficiency during the whole converter cycle, as well as excellent environmental performance. This is also essential in establishing good occupational safety and health.