What is WearSense™, and how does it work?

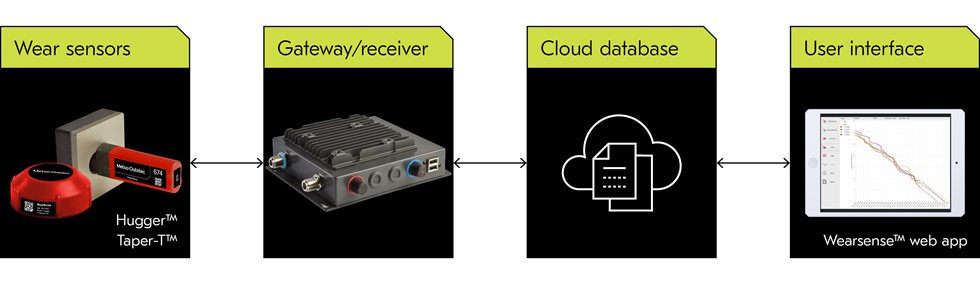

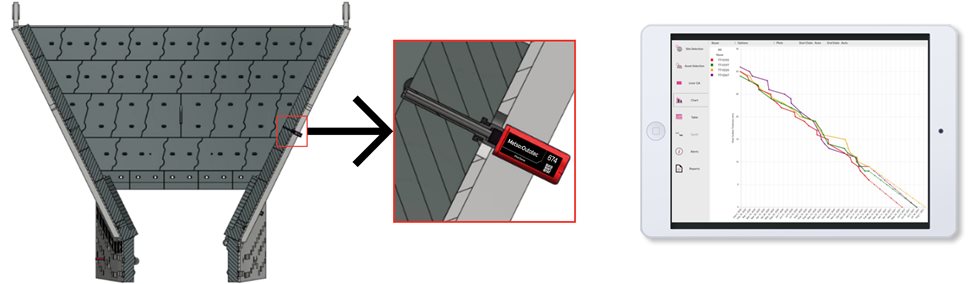

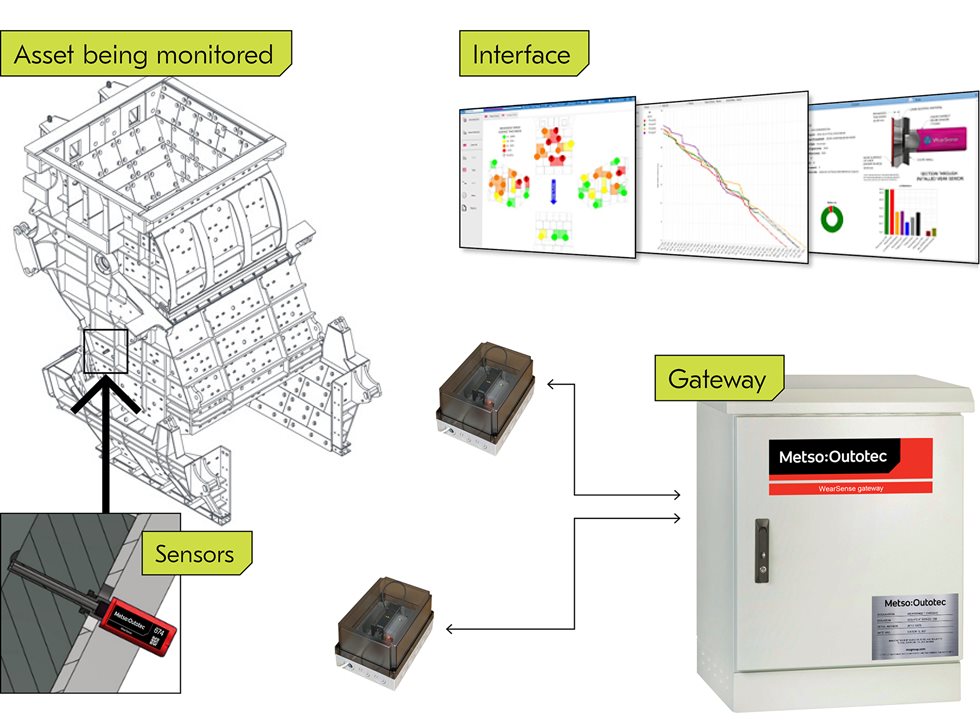

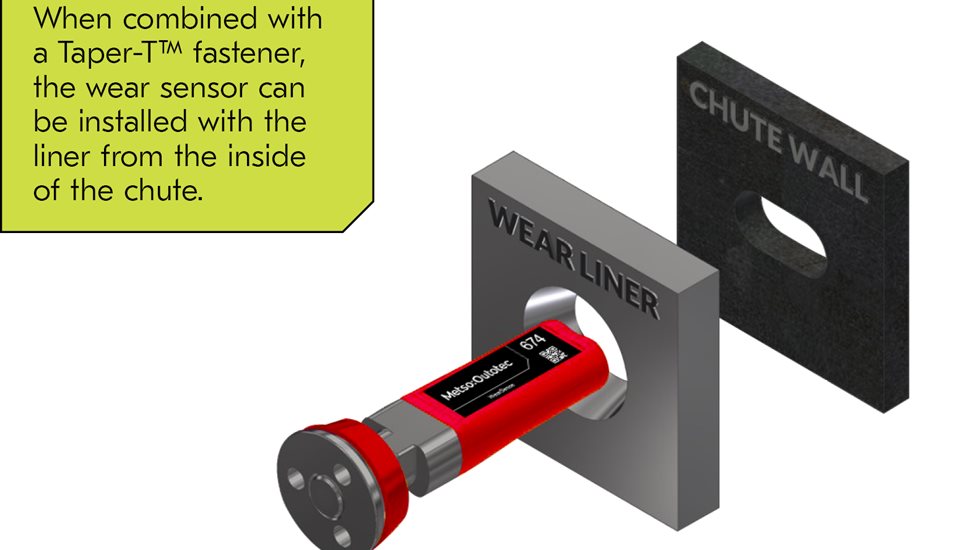

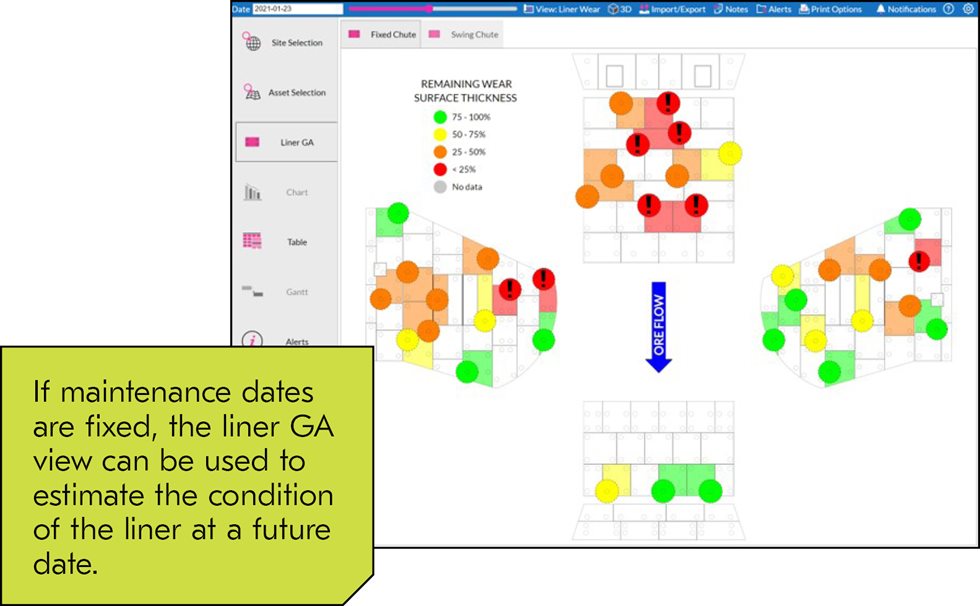

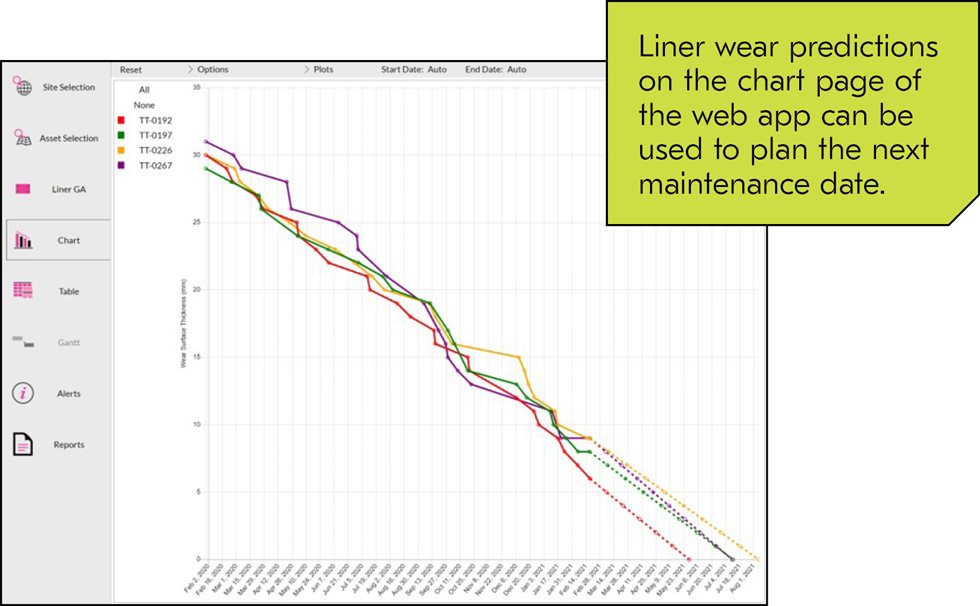

WearSense is a self-contained wear management system consisting of proprietary IoT sensors that monitor wear and other key parameters, a gateway that connects to cloud-based storage and processing algorithms and a web-based user interface. It is primarily designed to monitor the wear in chute liners and provides near real-time information on remaining material thickness and the ability to estimate the remaining liner life.