Benefits

Using fewer liners means less transportation, raw material inputs and waste

Provides real-time forecast of wear and expected liner change-out timing.

No need to stop the equipment to perform wear plate inspections.

Reduces working time in confined spaces, hot environments or at heights.

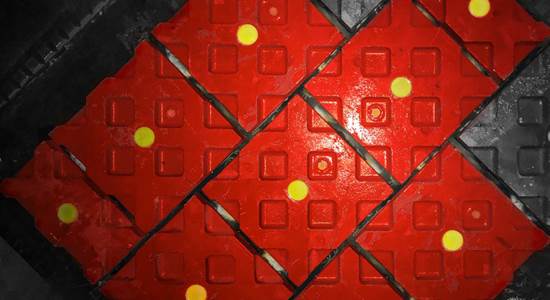

Metso wireless wear sensors are simple to use and fully self-contained, with a battery lasting up to 5 years. They can be used with any ceramic or metallic liners and multiple installation options are available. The sensors have glass filled nylon housing for durability. We offer two different types of sensors:

- The Taper-T™ sensor has minimal cross section area that enables it to be easily inserted through holes. It works directly with Taper-T™ attachments or can be used as a “stand alone” sensor

- The Hugger™ sensor has a low profile to minimize surface projection

The receiver communicates wirelessly with the sensors that can be located up to 300 meters away. Each receiver can support up to 100 sensors. The gateway collects the information from the receiver and sends it to the cloud. Multiple receiver units can be connected to a single gateway.

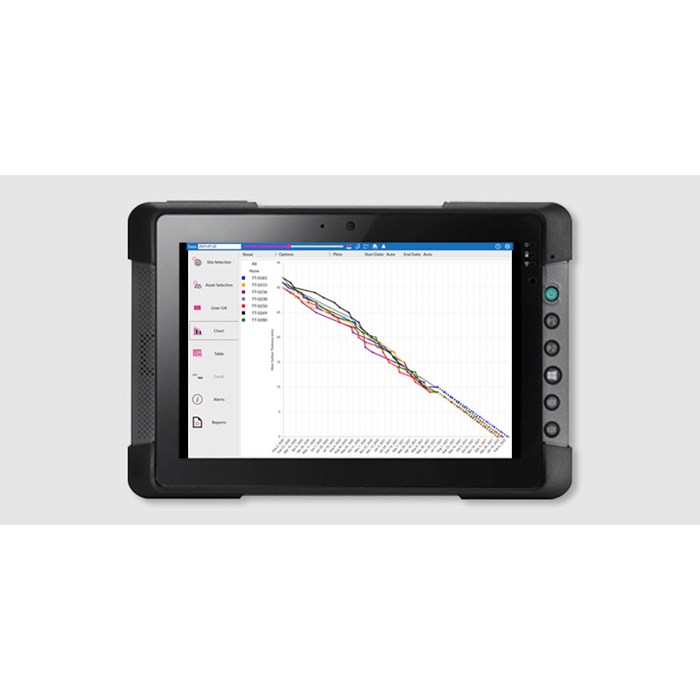

The easy-to-use interface gives you access to all the data you need about your liners’ wear performance. It also notifies you of potential issues and helps you predict when the liners need to be replaced.

The interface is accessible through a web app which makes it available from any computer or smart device with an internet connection. Features of the interface include:

- Indication of remaining liner thickness at each sensor location

- Ability to set email alerts based on wear levels

- Time series chart of liner thickness with end of life prediction

- Sensor diagnostics including battery life estimate

- Ability to export wear data or access it directly via an API