Flow pattern

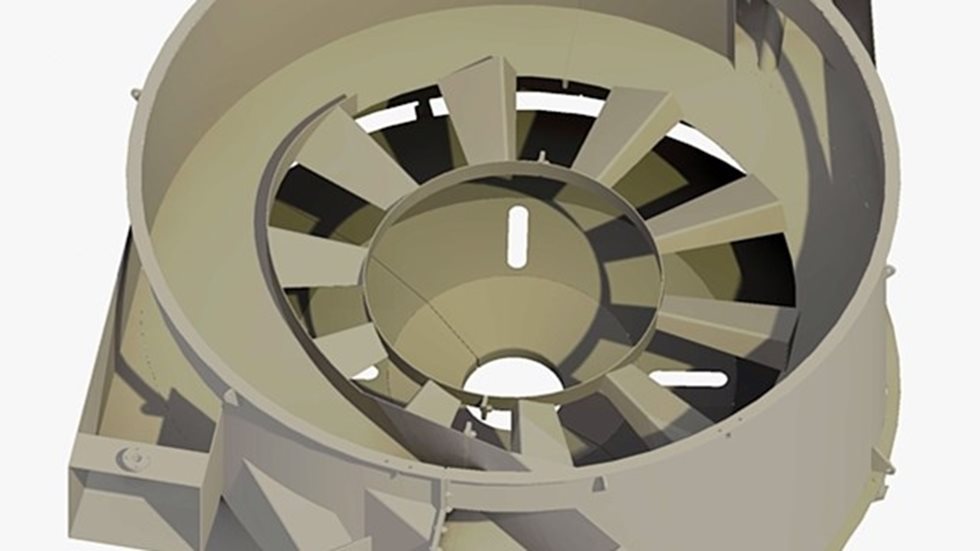

Figures 1 and 2 show an elevation view of the flow pattern and solids concentration in the unmodified and retrofitted feedwell. It is immediately obvious that the retrofitted Vane Feedwell TM has much better solids retention, with the majority of the feedwell solids close to the desired 3 % w/w for optimal flocculation. The shelf and vanes have held the feed stream up in the top half of the feedwell and the swirl is maintained right the way around the surface, ensuring effective feed solids and flocculant distribution and mixing. By comparison, the unmodified feedwell has virtually no solids in the top half of the feedwell, with this zone being bypassed and not effectively utilised for flocculation.

Shear

Shear is a natural by-product of turbulence dissipating the feed momentum/kinetic energy, and it is also a critical factor in flocculation. Turbulence provides mixing, both of feed and dilution liquor, but also flocculant and feed slurry. Ideally, shear rates should be moderate in the top of the feedwell where the flocculant is added, and then lower in the bottom zone to ensure the aggregates safe exit.

Figure 3 shows the unmodified feedwell, with figure 4 displaying the improvements from the Vane Feedwell TM retrofit. Without it, the shear rates are essentially too low throughout the feedwell.

Fitting the Vane Feedwell TM components improves this situation considerably. There are higher shear rates in the top of the feedwell which, when associated with the better solids retention in this area, will result in improved flocculation and better feed momentum dissipation. Finally, the shear rates are decreased in the exit region, indicating a reduction in flocculated aggregate breakage when discharging into the thickener body.

Tiwest thickener upgrade

Tiwest undertook the thickener upgrade at their North Mine in May 2008 to coincide with an extended plant shutdown. In addition to the new Vane Feedwell™, an improved flocculant addition arrangement, enhanced instrumentation and new static and upright rake pickets were installed to improve underflow densities.

Process results

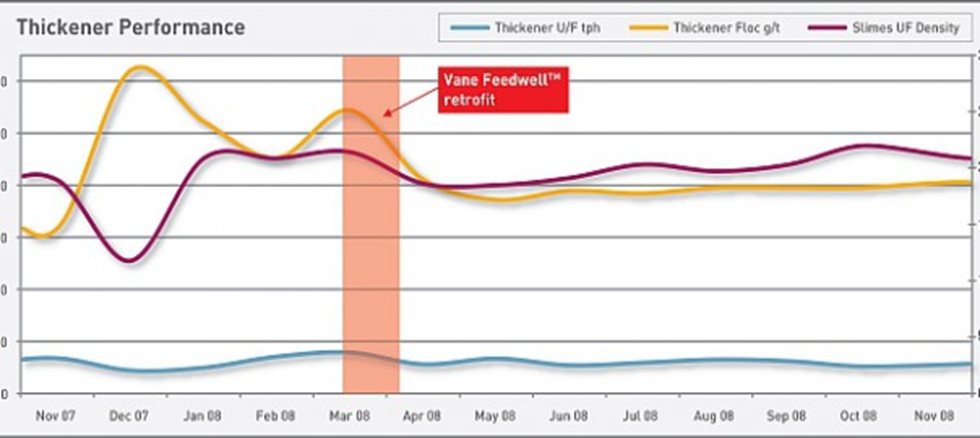

Process data was taken, both pre and post-Vane Feedwell TM retrofit, from online instrumentation. Laboratory flocculant demand is also included, as this is Tiwest’s own internal characterization of the slimes feeding the thickener. This has been used as a reference to determine if ore variability impacted the results.

Thickener flocculant dose

Slimes thickener flocculant dose prior to the retrofit was averaging 490 g/t, with a standard deviation of 114 g/t. Post installation flocculant dose reduces by approximately 20% to an average of 393 g/t and process stability occurs with a standard deviation of only 12 g/t.

From an operational perspective, the reduction in flocculant consumption is estimated to be primarily as a result of the new feedwell, with contributions also from the improved flocculant addition arrangement, pickets and instrumentation.

Thickener underflow density

Underflow density shows a major difference post Vane Feedwell TM installation. Prior to the retrofit, the slimes underflow density averaged 18% w/w with a standard deviation of 3.7% w/w. Post retrofit, a density of 20% w/w was averaged, perhaps more interesting, with a standard deviation of only 1.2% w/w. This implies that not only a higher underflow density can be achieved but also more consistently, resulting in improved process operability. This again highlights the Vane Feedwell’s ability to smooth out process variability and hence operate across a wider range. It is believed the addition of rotating pickets also helped underflow density.

Underflow density increase enables slimes deposition to be maximised. This is a very important factor for both Tiwest’s operating costs and sustained operation, since the water lost to thickener underflow is evaporated in slimes cells and lost from the process. Tiwest had experienced plant shutdowns due to mine site water shortages during the summers of 2007 and 2008.

Thickener underflow throughput

Thickener underflow tonnage rates are fairly constant across the time period at approximately 60 t/h, indicating that feed rates are not significantly different pre and post installation. Feed rates therefore do not bias the data one way or the other.

Flocculant demand

Flocculant dose, as determined through Tiwest’s laboratory characterisation procedure, can be viewed as being essentially consistent at an average of 300 g/t both pre installation and post. The variability in laboratory flocculant demand needs to be viewed against the actual thickener flocculant dose and the other variables to compile a total picture.Of particular interest is a comparison of the laboratory flocculant demand versus the actual thickener dose. During the post installation period, despite varied laboratory flocculant demand, actual thickener dose is very stable. This indicates that the Vane Feedwell TM has the ability to operate across a range of conditions and also is less sensitive to changes in flocculant demand requirements.

“A great success...”

Coupled with the plant data are the visual observations and experiences from Cooljarloo site personnel. The following is a direct quote: