As the first greenfield mine in the country in four decades – and boasting one of the highest open pit gold grades in the world – Ada Tepe required a cutting-edge solution capable of real-time and reliable elemental analysis measurements.

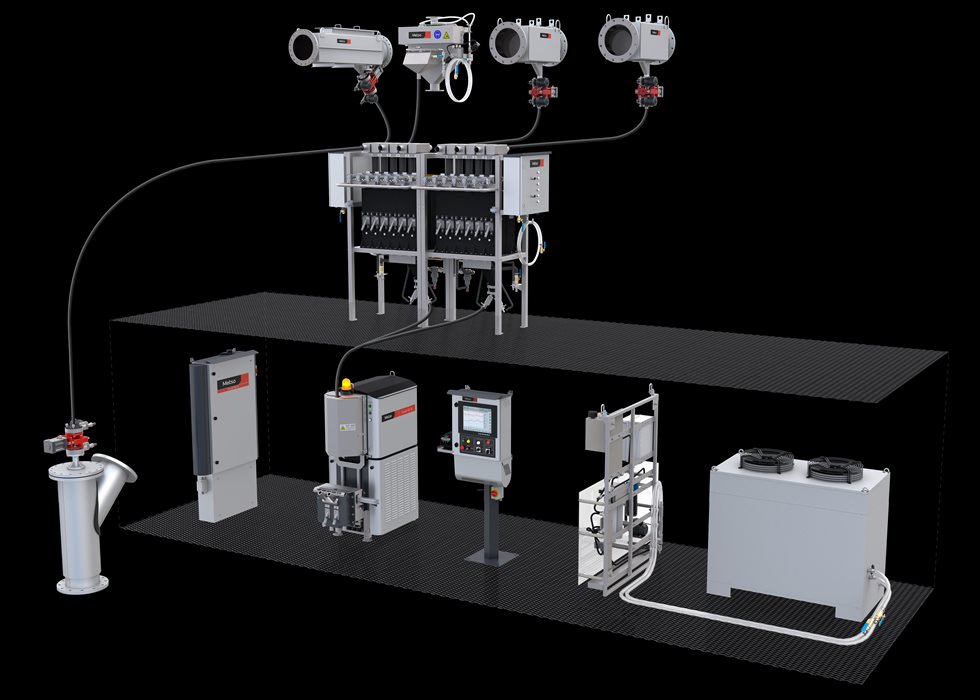

Specifically designed for on-stream analysis, the Courier® 6G SL analyzer revolutionizes the direct measurement of gold, platinum, and other valuable metal concentrations in ore feed, concentrate, and tailings streams. By delivering fast and accurate elemental analysis data, the analyzer enables mining operations to have more efficient process control, thus enhancing process stability and maximizing recovery rates. The typical measurement time for gold in feed is one to five minutes, for concentrate streams 30 to 60 seconds and in tailings five to 20 minutes due to lower elemental concentrations. Total cycle time for feed, concentrate and tailings streams can be as low as 30 minutes, which enables operators to react much faster to changes in the process.

The Courier 6G analyzer's advanced technology, which features a high-power X-ray tube and measurement channels optimized for direct measurement of gold and platinum group metals, allows for the detection of low quantities of elements that were previously undetectable.

"This is our first analyzer that can measure gold directly in flotation tailings,” says Juha Timperi, Director, Analyzer Solutions at Metso. “With previous analyzers, you could measure gold in concentrate, for example. But in tailings, the gold level can be below parts per million (PPM), which has been too low for traditional on-line analyzers. With the new Courier 6G SL analyzer, our customers have been able to measure gold concentrations on sub-ppm levels as low as 0.2 grams per ton. This enables new ways to control flotation process in real-time and prevent losing gold to tailings.”