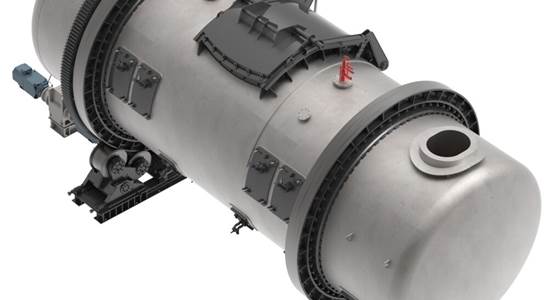

Refurbishments to prolong the life of your equipment to help you reach your sustainability targets

Refurbishments significantly reduce material requirements when compared with the procurement of new equipment

We offer a standard factory warranty on all refurbished parts and workmanship

Up to 70-80% cost saving over the cost of new equipment

Our refurbishment service can significantly extend the life of unreliable, aging equipment

- Extends equipment lifetime

- Reduces maintenance and increases wear life

- Ensures higher availability

- Improves performance